|

|

|

Blade Performance Vs Wood Type and Design |

Post Reply

|

Page <1234> |

| Author | ||

igorponger

Premier Member

Joined: 07/29/2006 Location: Everywhere Status: Offline Points: 3252 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/04/2014 at 11:42pm Posted: 12/04/2014 at 11:42pm |

|

|

ЦИФРЫ ПРАВДУ ГОВОРЯТ.

Зачем мне ваши обширные обзоры цветастые, многословные? это фокусы придуманы для девочек охмурять. Девочки любят ушами. Для мальчиков и мужиков нужна простая и ясная оценка продукта, несколько скупых цифер, десятибальная шкала. КАК ДЕЛАТЬ ОЦЕНКУ. Берем эталонную резину типа тенержи. Все игровые характеристики 10 баллов. И делаем оценку продукта сравнительно к эталону. Человек кто умеет оценивать продукт в баллах это настоящий эксперт достойный уважения. Краснобай многоречивый это не эксперт ни разу.. У немцев лучший оценщик работает на фирме CONTRA в Гамбурге. Это подлинный талант. Каталог КОНТРА самый лучший каталог теннисной продукции.. ТРЕБУЕТСЯ ОПЫТНЫЙ ОЦЕНЩИК Буду по гроб жизни благодарный если кто сделает сравнительную таблицу для китайской резины, по всему списку Еченг. Это надо будет лично посетить Китай и работать там на складе еченга. тестировать резину за теннисным столом. Кто смелый? http://www.contra.de/katalog/Contra_Katalog_2014/#64/z Edited by igorponger - 12/04/2014 at 11:50pm |

||

|

||

| Sponsored Links | ||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 12:26am Posted: 12/05/2014 at 12:26am |

|

|

Edited by JRSDallas - 12/05/2014 at 12:34am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 1:01am Posted: 12/05/2014 at 1:01am |

|

|

> Derive the physics of ball to paddle collision as I have done with blade construction. The insight is the equation.

This is not only non-trivial but if you look at the hollow sphere sim, it's questionable whether it's even possible. However a simple string model isn't going to be off by much and is consistent with basic material stress/strain principles, and certainly not by the near order of magnitude discrepancies in the ball/blade frequencies. I mean, calculating the basic mechanical displacement of certain ball impact speed (~10m/s) over a certain distance (~mm) isn't a trick, it's a basic sanity check. In this case, unless the racket somehow holds onto the ball for many ms (a violation of physical continuity), there's no way it overlaps the bending frequency/period of the blade. > It exactly shows how frequency v changes when you change ANY other parameter. I can see the equation and I don't doubt that the frequency changes with respect to size or any number of params, but my point is whether frequency as indicator has predictive power over varying blade size. We can do the tiny vs massive blade (or table) test, but I think we both know the likely result. There might be some effect at the extremes (esp small mass), but at all sane sizes it's all going to be ~same. As another sanity test, the "sound cone"* of the impact is ~2m at best over evident dwell length (and half that for an interaction to come back), and that equation certainly scales beyond this. *conceptual equivalent of relativistic light cone. Edited by AgentHEX - 12/05/2014 at 1:12am |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 1:10am Posted: 12/05/2014 at 1:10am |

|

|

Also a brief note to igor and those similarly skeptical of what science can do: consider the amount of human progress in the last few hundred years with science, vs all of human history prior when people relied on their gut. I don't think there's much doubt where they'd prefer to live.

|

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 2:48am Posted: 12/05/2014 at 2:48am |

|

|

BTW, I looked at the equation a bit closer and don't understand how

the

Parallel Axis Theorum is being applied. The "d" is

supposed to be magnitude of displacement to the center of rotation

(which is why

it's squared), but surely the ply layers don't rotate with respect to

the centerline. I can see you're trying to bring in a

corrective factor, but this doesn't look to be it (basically you're

offsetting the outer layers in the wrong direction, towards the blade tip). Fortunately this effect is mitigated by relatively small size of d.

Edited by AgentHEX - 12/05/2014 at 2:53am |

||

|

||

lineup32

Gold Member

Joined: 12/06/2012 Location: Calif Status: Offline Points: 1195 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 12:34pm Posted: 12/05/2014 at 12:34pm |

|

|

thanks for this thread, very interesting points of view and meaningful for players if they pay attention and follow. The link to : http://cofrest.info/md3.htm; thanks! very informative

|

||

|

||

Baal

Forum Moderator

Joined: 01/21/2010 Location: unknown Status: Offline Points: 14336 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/05/2014 at 12:56pm Posted: 12/05/2014 at 12:56pm |

|

|

Igor is the guy who once repeatedly demanded numbers on another topic ("because I am construction engineer"); criticized all of China for not knowing science; and now that he is actually been given something quantitative (in a more abstract form) finds them not manly or plain enough. Oh well.

|

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/06/2014 at 10:47am Posted: 12/06/2014 at 10:47am |

|

|

HEX said "......there's no way it overlaps the bending frequency/period of the blade."

Already fully discussed but also irrelevant to issue of how to design a blade. You are missing the big picture. I don't care about rebound time, I care about energy losses arising from collision. Energy is lost to the blade when you couple collision energy into the blade's vibration modes and this always reduces COR. There is the discussed resonant case of energy return from a single vibration mode but the remaining spectrum of blade's vibration modes won't simultaneously be resonant, they will just be radiating absorbed collision energy as sound. Less energy is coupled into stiffer blades and so they have generally higher COR. Someone may not like fast blades. OK they can use the information to pick a slow one before spending their money. Hex said "..but my point is whether frequency as indicator has predictive power over varying blade size." Most blades fall into a fairly small size range so from a practical standpoint, YES the frequency of a blade is a good predictor. My empirical data for over 30 blades also supports this. If you personally are choosing between two identically constructed laminations but one blade face is the size of your palm and the other is the size of a dinner plate well then you have two choices: (1) Try them. (2) Calculate the expected frequency shift due to the dimensional differences. Otherwise stop worrying about if frequency is predictive of COR. It is (in general). Hex said "I looked at the equation a bit closer and don't understand how the Parallel Axis Theorum is being applied." The distances "d" are perpendicular to the plywood face of the blade and are measured from the center of the plywood stack to the center of the layer in question. The equation is not a correction factor, its just the math. Lookup moment of inertia, it explains why steel I-Beams and engineered wood I-joists look the way they do. Hex said "Fortunately this effect is mitigated by relatively small size of d." Understanding "d" (the placement of a layer within a plywood) is hugely important to how that layer contributes to the overall stiffness and blade speed. Moving a particular layer from the center outwards, rapidly increases the contribution to blade stiffness by that layer. Balsa and kiri are used as thick center plies because they are light and they provide a surface to glue on stiffer layer (such as rosewood, carbon, etc onto) that makes the plywood of the blade much faster without getting it too thick. Designers often then glue a somewhat softer wood on top of the carbon or ebony layer so as to give the blade a softer impact feel while not actually slow down the blade much. Designers that place stiff layers like carbon or ebony at the center of a plywood are making the least use of the strength of that material. Most blades don't use stiff layer at the center because its stupid engineering. Of course there is no shortage of people you can sell pyramid power to so it may be just smart marketing. Lineup32 provided the web link: http://cofrest.info/md3.htm; Thanks Lineup. Yes I know that webpage and I looked at molecular modeling when I was thinking about solving issue of rebound after collision. I think the best modeling path is to use a finite element analysis software that includes the ability to model elastic and inelastic collisions. I can't afford a probably $10K license and there are no "student" copies of such software tools that I know of. Edited by JRSDallas - 12/06/2014 at 11:01am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

BH-Man

Premier Member

Joined: 02/05/2007 Location: United States Status: Offline Points: 5042 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 1:28am Posted: 12/07/2014 at 1:28am |

|

|

JRS !!!

|

||

|

Korea Foreign Table Tennis Club

Search for us on Facebook: koreaforeignttc |

||

|

||

Tassie52

Gold Member

Joined: 10/09/2010 Location: Australia Status: Offline Points: 1318 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 5:22am Posted: 12/07/2014 at 5:22am |

|

|

1

If blade frequency can be

used to predict blade speed because of its relationship to system stiffness,

then does it follow that calculating stiffness will also give us a measure of

blade speed? 2

The formula quoted above

uses “density”. Are you using

average dried weight (measured in kg/m3) rather than specific

gravity? 3 How is the formula applied? (I said I had trouble with numbers!) For example, if I know that PO cedar has an average dried weight of 430 kg/m3 and MoE of 11.35 GPa, then stiffness = √(430/11.35) ? Again,

I’m sorry if I have no idea what I’m talking about, but I would be really

interested to know if this produces some meaningful way of comparing different

timbers. Thanks. |

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 10:57am Posted: 12/07/2014 at 10:57am |

|

|

My answers are in RED.

Tassie52 asked: 1 If blade frequency can be used to predict blade speed because of its relationship to system stiffness, then does it follow that calculating stiffness will also give us a measure of blade speed? Yes system stiffness is a measure, but calculating it or measuring it is more difficult than listening to the sound the blade makes. Just trying to be practical. In the end, while I have calculated and made actual measurements, I only did it for the learning. It is faster and easier to just pick blade speed by hearing the tone. (If I can't hold it and hear the tone, then I fall back on looking at the plywood construction and knowing what makes it stiffer). 2

The formula quoted above

uses “density”. Are you using

average dried weight (measured in kg/m3) rather than specific

gravity? I use any weight reference I can find (dried, specific gravity, etc) and convert to the units needed. I don't use green weight as we don't use green wood in our blades. 3

How is the formula

applied? (I said I had trouble

with numbers!) For example, if I

know that PO cedar has an average dried weight of 430 kg/m3 and MoE

of 11.35 GPa, then stiffness = √(430/11.35) ? You can see the spreadsheet tables of calculations that I did for various rectangular approximations to blades earlier in the thread. However, I have only done these calculations for that original thread in late 2008. I did it at the time to illustrate that the formula results made sense, i.e. A 10mm single ply hinoki is fast - Yep the calculations predict that. An 8mm single ply hinoki is pretty slow - Yep the calculations predict that. The Schlager Carbon is pretty fast - Yep the calculations predict that. If you are designing a blade that you will build but want to optimize something, then go ahead and work out the calculations for some ply combinations you are considering. If you understand the equation though, you can see how the ply combinations effect the result and pick what you want to do. If your goal is to build a blade that is faster than Schlager Carbon, build a stiffer plywood. The lightest way to do that is to increase the thickness of the light center ply so that the carbon layers are moved further apart. Or, if you have a fabric with higher modulus than carbon, then use it instead of carbon and don't increase center ply thickness, or do both and get something much faster. If you don't like how carbon feels but still want a result that is still faster than Schlager Carbon then use Carbon-Aralyte and increase the center ply thickness even more to offset the lower elastic modulus of Carbon-Aralyte. The formula will help you determine exact thickness changes needed but you already know what to do. Now one can make accurate measures of blade frequency spectrum (handle in clamp, ball bounce at center of percussion, microphone, Fourier decomposition into frequency spectrum, identify spectral peaks - see pictures from the original thread). I also did that for 30 or so blades in late 2008/early 2009. I was not looking for the calculated frequency of my rectangle approximation to predict the measured frequency of a real blade with the same plywood, I was trying to see the behavior differences between blades matched what the calculations predicted. Yes, Schlager Carbon is far faster than Clipper. Yes, EPOX TOPSPEED isn't very fast even though the manufacturer (and CONTRA) rate it OFF+. Perhaps I got a bad one? No. The review is wrong. Can you hit a fast ball with Clipper and EPOX TOPSPEED, absolutely but you'll spend more energy doing it. So my recommendation is to understand the system behavior, not to calculate a particular output that results from particular inputs. I only bounce a blade (of normal size) on my head so that I can hear its tone (pitch, frequency). If the tone is higher than another blade, then it is faster than that other blade. If I am buying out of a catalog, then I look at its overall thickness and the layers in the plywood. Innerforce ZLC is absolutely slower than Amultart primarily because its ZLC layers are closer to the center and it is thus less stiff. Edited by JRSDallas - 12/07/2014 at 11:12am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 3:44pm Posted: 12/07/2014 at 3:44pm |

|

|

> You are missing the big picture.

This is a good idea so I'll format the reply in order of stack ranked priority from broadest issue to most technical detail: 1. The key point to noting that ball/blade/rubber occupy different freq/periods is dispelling the erroneous mental image of TT ball interaction from which most others stem. If you look at nearly every equipment review/comment, even opening posts here, the basic idea is that ball rebound is directly coupled to blade and rubber characteristics (specifically the blade/rubber flexes back to repel the ball). This misconception has clear systemic consequences, not unlike the basic idea that everything revolves around the earth. If anything, removing that notion of coupling makes reasoning about the system easier. 2. My argument on frequency isn't that it's an invalid or even poor indicator/predictor, only that it has its own drawbacks. The first point was that conceptual correlation to ball rebound is not causal as mentioned in the posts. The second was it has coincidentally decent mathematical shape: from POV of practical "accuracy", all functions with ~this shape: http://www.wolframalpha.com/input/?i=-1%2F%28x%2B1%29+%2B+1 will predict relative COR across the range better than the indicators mentioned. They all happen to work OK for relative comparisons because slope ~= 1 in the blade thickness range, and how all contiguous functions are approximately linear for relatively small deltas. However mere numbers do not provide conceptual understanding, which is really what we're after here. This was why I mentioned that some of the necessary input params to freq can be misleading to such a goal. 3. On the d factor, consider a simple example: a rotation axis starts at center and moves to d=2, thus d^2=4. If it moves a further 2 units out in same direction d=4, d^2=16. However if it moves 2 unit perpendicular to first direction d= sqrt(2^2 + 2^2), d^2 =8. Ie. direction matters. The rotational axis in our case is initially "moved" to the end of the blade along the blade length. The "d" you're using is perpendicular to this direction. Also note the offset is not calculated relative to any axis, but to an axis through center of mass.* 4. >Understanding "d" (the placement of a layer within a plywood) is hugely important to how that layer contributes to the overall stiffness and blade speed. Yes, but not to frequency as noted (how would it from a physical sense perspective?). If you can imagine the particle sim of the blade the collision, particles closer to the surface surely matter a bit more than those deep. However this is a matter of degree, and the rigid coupling between those particles (ie solid) tends to make the object as whole homogenous. It's also likely non-trivial to model, esp with clean discrete equations from first principles. -=- edit: To flesh out this last point, recall that rotational inertia of an object about an axis cannot simply be reduced to operations its center of mass. Ie the edges of those outer plies certainly contribute quite a bit more than the middle which is d (a few mm) away, even if the plies somehow rotate around the center axis. To do the calc correctly we need to bust out geometric calculus. Edited by AgentHEX - 12/07/2014 at 4:20pm |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 3:50pm Posted: 12/07/2014 at 3:50pm |

|

|

Just to clarify on the I-beam point. The x^3 relationship is already encapsulated in the first term, this is about the "offset" second term.

|

||

|

||

cole_ely

Premier Member

Joined: 03/16/2005 Location: United States Status: Offline Points: 6898 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/07/2014 at 4:05pm Posted: 12/07/2014 at 4:05pm |

|

Makes sense that was you.

|

||

|

Wavestone St with Illumina 1.9r, defender1.7b

Please let me know if I can be of assistance. |

||

|

||

Crowsfeather

Super Member

Joined: 08/03/2013 Location: Thailand Status: Offline Points: 448 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/15/2014 at 6:53am Posted: 12/15/2014 at 6:53am |

|

|

I will never understamd those math, but in short, thickness and composite type give a stiffness, in which effect how fast ball leaving your blade.

And also stiffer blade tends to give higher pitch of frequency , im i right??? |

||

|

I'm no longer an EJ and I'm proud .

|

||

|

||

Crowsfeather

Super Member

Joined: 08/03/2013 Location: Thailand Status: Offline Points: 448 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/15/2014 at 6:55am Posted: 12/15/2014 at 6:55am |

|

|

After all this, can you further evaluate the top wood and the inner ply, how it effect ball trajectory.

Im talking about first speed, the speed of the out going ball And second speed , the bouncing speed after landing. Or it is just pure effect of rubber |

||

|

I'm no longer an EJ and I'm proud .

|

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/16/2014 at 3:33am Posted: 12/16/2014 at 3:33am |

|

|

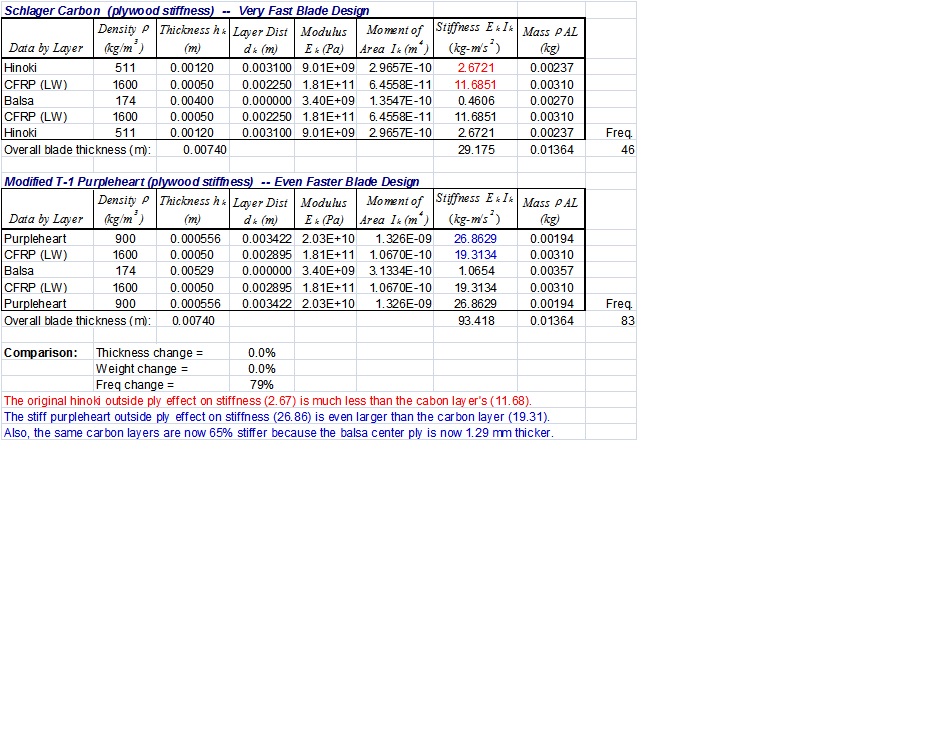

Arrangement of the plies and seeing where the stiff plies are placed is the thing to notice.

Everything has a stiffness. If you have two stiff plys, placing them at the outside of the blade increases blade stiffness the most. All wood blades that put rosewood or ebony or purple heart as the outside plies are using this approach. Since carbon is not legal as an outside ply, it has to be covered with some outside layer but on fast-stiff blades the carbon plies are the first layer below the surface. Some blades move the stiff carbon layers closer to the center which makes the blade less stiff. Soft and light plies are mostly used at the center of blades since less than 1.5% of stiffness for these blades comes from their center ply. To illustrate the impact of materials selection and even small thickness changes, lets compare calculations for two really fast blades - Schlager Carbon and a blade with the same overall thickness but thicker balsa center and a thinner but stiffer wood outer ply. These changes make huge change to total stiffness that nearly doubles the frequency even though total weight and thickness are unchanged. Simply increasing balsa center ply thickness by 1.29mm and changing the outer ply from 1.2mm hinoki to 0.556mm purpleheart has increased blade frequency by 79% and increased stiffness by 300% (93 vs 29).  Edited by JRSDallas - 12/16/2014 at 3:40am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

jrscatman

Premier Member

Joined: 10/19/2008 Status: Offline Points: 4585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/16/2014 at 4:00am Posted: 12/16/2014 at 4:00am |

|

|

Thanks for sharing all this information. Very informative and interesting.

One question I have is the head shape - how does it effect performance. In Tennis/Badminton Yonex has what is called an isometric shape - basically it's a rounded rectangle - they claim it increases the size of the sweetspot. In TT - it very similar to some JPen blades. If you have any thoughts on the optimal head shape, would be interested in your thoughts. |

||

|

Butterfly MPS

FH: Donic Acuda S1 BH: Palio CK531A OX |

||

|

||

AL_in_MN

Member

Joined: 11/13/2008 Location: United States Status: Offline Points: 74 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/16/2014 at 2:26pm Posted: 12/16/2014 at 2:26pm |

|

You will have to check with JRS, (the actual engineering wizard), but when I first read his original research posts on this, I gathered from his test results (or thought I did) that the Yinhe W-1 had the largest sweetspot and overall optimal performance characteristics of all the blades he tested; after I bought one (and now own 3) and played with it, I found my blade forever :^) |

||

|

Blade:Yinhe W-1

Rubber:Air Illumina 2.1 |

||

|

||

jrscatman

Premier Member

Joined: 10/19/2008 Status: Offline Points: 4585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/16/2014 at 4:24pm Posted: 12/16/2014 at 4:24pm |

|

Al-in_Mn Thanks - I'll take a look at that blade. I know a friend prefers to play with J-O Waldner shape. I am interested learning more about the wood type in blade design - but it's a lot of info - might take me a while to understand what's going on.

|

||

|

Butterfly MPS

FH: Donic Acuda S1 BH: Palio CK531A OX |

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 12/16/2014 at 8:13pm Posted: 12/16/2014 at 8:13pm |

|

I believe you will get to an optimal head shape quicker by looking at how head shape effects swing weight and the likelihood of catching the blade edge on the table during close over the table play. There was a trapezoidal head shaped TT racket back in the 70's, but it was not common. Over the table play was harder with it since the head was widest at the tip of the blade. I suspect you could easily his corner on the table surface when pushing or making a flip or over the table backhand banana loop. In the end, there have been a few million ping pong players and most of the rackets have been somewhat rounded shapes for multiple racket sports. If you swing is such that your racket is horizontal over the table (Japanese penhold grip, then the rounded rectangle makes more sense since the long flat edges are easier to keep parallel to the table surface during over the table play, and the length gives you more tip speed when playing off the table.) Remember that my equation and calculations already simplify the blade shape to a rectangle. This let me end up with an equation showing the key relationships between the variables (the source of real understanding). It also lets one use simple calculations to compare differences between similarly shaped blades due to the construction of their plywood layers. Now if we change the shape of the blade to accurately reflect a real TT blade, the Moment of Area term I k changes to an integral which when calculated results in a new I k value reflecting the shape. The A and L term will also be effected. Still, the final result is only a shift in the frequency of the various vibration modes. No real magic. If we are comparing between blades of similar size and shape, then we are back to only looking at the effects of the differences in plywood construction. However, if you want to compare between blades with large shape or size changes, then different Moment of Area I k values between the blades will occur even if we don't make any changes the plywood layers. Edited by JRSDallas - 12/16/2014 at 8:20pm |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/19/2014 at 2:29am Posted: 12/19/2014 at 2:29am |

|

|

> If you have two stiff plys, placing them at the outside of the blade increases blade stiffness the most.

This is slightly true, but to a much less extent than most people assume. To understand this intuitively, it's worth pondering what it means for a substance to be "solid". As alluded to before, solids have very strong molecular coupling which make the "stiffness" of the outside very much connected to the stiffness of the inside. That's why plate theory with a simple x^3 relationship works out, with no need to integrate by layer. When it comes down to collisions it's stiffness that matters: it relates directly to elasticity which is the namesake difference between elastic and inelastic collisions. If you can imagine a particle interaction/simulation which is the end-all physical arg, the forces distributes through the blade with only a lesser effect intrinsic to the surface itself. The shape also doesn't matter in the same way size doesn't matter. A ball isn't going to bounce much different off a round blade vs square any more it does a round vs square table, even if frequency changes. ---- As to how all of this matters: for heavier active swings it mostly doesn't. The human racket stroke is capable of orders of magnitude range between light and heavy. Compare this to two blades one maybe twice as fast, which is already a massive difference in equipment. However on a light impact into the blade like touch shots or fairly thin brushes the limited range of adjustment meets with the nature of precision: +-10 matters a lot more between 0-10 than >50, ie. twice as hard on a heavy stroke is much easier to control than twice as hard on a minimal one. This is why ironically somewhat lesser players with typically lighter strokes are more sensitive to blade differences esp. |

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/20/2014 at 2:29pm Posted: 12/20/2014 at 2:29pm |

|

Note: I have added numbers and underlining above - JRSD

(2) HEX talks plate theory but does not recognize that the plate theory equation he has seen assumes an isotropic and homogeneous material (i.e. a uniformly

thick single material with uniform physical properties in all directions) in order to end up with a simple X^3 relationship. (Note: I also assume HEX means x=blade thickness. In this thread I use h as the symbol for blade thickness). NOTE: A

single ply blade is the closest TT example to a homogeneous plate, but wood is still non-isotropic. In my original derivation I discussed but then ignored the non-isotropic aspects of wood in order to keep the math simple. I did however solve for the non-homogeneous lamina case where the blade is made of different layers. SO………when a plate is non-homogenous lamina (i.e. if it has layers of different materials), you have to account for each layer’s contribution to plate modulus Eblade (and to be actually correct also have to account for each layers moment of area Iblade) so as to obtain an overall blade modulus Eblade for use in a Mindlin–Reissner plate theory formula such as: D = bending stiffness of a plate (also known as

flexural rigidity) = Eblade * Iblade. In the plate theory formula shown above the moment term I, is already captured in the value 2/(3*(1-v^2) so you don't see it in the formula. Still since the equation is based on assuming a calculation at the center of the plate, it will miss the weighted effect on increases or decreases in E from layers that are not at the center of the plate. h = blade thickness E = Young's modulus (of the plate) = Eblade obtained through summation through the blade layers – (exactly the issue that HEX ignores) v = Poisson's ratio. So in estimating blade stiffness, can we only look at blade thickness h as HEX says? No, you have to look at both E and h and the plate theory equation clearly shows this. Different materials have different E, and if one compares two materials of thickness h, the material with the higher E will be stiffer. Similarly if one compares two blades of equal overall modulus Eblade, the thicker blade will be stiffer. Finally, for any given blade construction, increasing thickness h very quickly makes it stiffer – i.e. stiffness grows as the third power of thickness (as originally posted 05/22/2013 at 7:24am, paragraph 6). Now if you are comparing blades made from woods with similar E, that are constructed similarly, they will have similar modulus Eblade, and in such cases, h is the decider as to which blade is stiffer. (3) Here

HEX makes the connection that stiffness matters in collisions (finally). Unfortunately, while h is often known, no TT catalog lists, or TT player measures blade modulus

to let us even use the plate theory formula as a practical tool. SO………how then can a TT player judge blade

speed before buying and trying? Hmmmmmmm………………….Wait I remember! Someone in this thread showed using math from the theory of beams (which is also the source of plate theory), that the stiffness of the blade (Eblade * Iblade) can be judged by the frequency of vibration that the blade makes when struck! As I remember, that formula also included structural terms that let us understand the connection between the mode frequencies and how the layers of the blade contributed. Further, I recall that from all of the examples calculated and empirical data presented that it seems to be true that to compare the stiffness of different (typical) TT blades, all we have to do is listen to which blade has the higher or lower pitched sound to know which blade is stiffer (generally observed to be faster) or less stiff (generally observed to be slower). Edited by JRSDallas - 12/22/2014 at 4:43am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

Krantz

Super Member

Joined: 05/14/2009 Location: Poland Status: Offline Points: 276 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/20/2014 at 5:20pm Posted: 12/20/2014 at 5:20pm |

|

|

I suspect that less stiff blades can give increased ball's dwell time (if it rises from 0.9 to 1.2 it is still 30% more which can be significant) which can result in ball's higher possible spin - and this is important because a ball which both travels fast and rotates fast carry more energy then just a fast flat shot and thus can be more difficult do deal with - so in a looping style one has to find his golden middle which enables him to maximize both his speed and spin (or overall ball's energy).

|

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/20/2014 at 11:08pm Posted: 12/20/2014 at 11:08pm |

|

Agree, and the heavy top spin from fast loop also lets you hit harder in many circumstances as it makes the ball curve downward and hit the table more than gravity alone would. A flat hit has to either be hit from above the net down onto the opposite side (and in this case it can be hit as hard as you can hit), or when no straight line to the opposite table surface exists, then hit in balanced way that gives gravity time to pull the ball down onto the other side before it goes long. As to which hit puts more energy into the ball, since the only energy in the collision comes from the moving ball and the moving paddle, an equivalent question is to ask what type of hit loses less energy. So, does the loop drive (which both tangentially stretches the rubber+sponge and compresses the rubber+sponge against the blade) lose less energy than 100% compression of the rubber+sponge against the blade? IF the rubber+sponge loses more energy during 100% compression than it does during mixed compression and tangential stretching, then the loop drive will leave the ball with more total energy. This is a great question for someone to give a reliable answer on (i.e. based on rigor with some corroborating measurement data). The ITTF did some modeling and measurement of ball rebound from Sriver and another rubber on a 50mm thick wooden block in 1996. They shot the ball both straight on to the rubber face (compression only) and at an angle to the rubber (compression and tangential stretching). I looked at the modeling, but I was not thinking about this question so I don't know if the article already answered this question. Article Title of the ITTF Article is: Collisional Properties Of Ball-Racket Interactions In terms of Normal and Tangential Coefficients of Restitution; Suguru Araki, Shinichi Sato and Hitoshi Yamazaki, International Journal of Table Tennis Sciences, No 2, 1996. Edited by JRSDallas - 12/20/2014 at 11:16pm |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/21/2014 at 4:33am Posted: 12/21/2014 at 4:33am |

|

|

> No it is exactly true and it matters when a blade uses different

material layers in its construction. I

calculated an example comparing two blades of identical thickness just two JRSDallas

posts ago.

You're assuming that those frequency calcs are directly correlated which is very much in question (they certainly aren't with respect to size, and who knows what else), ie. a case of begging the question. > HEX talks plate theory but does not recognize that the plate theory equation he has seen assumes an isotropic and homogeneous material I very much recognize this, so the issue is that my point hasn't been understood. To elaborate further, if what you're claiming about the relative significant of surface vs inner plies is true it should certainly show up in this category of theories as some relative weighted factor with respect to distance from center (then integrated over the thickness of the plate). > So in estimating blade stiffness, can we only look at blade thickness h as HEX says? No, you have to look at both E and h and the plate theory equation clearly shows this. Really? Especially when you make the exact same point I do?: "Finally, for any given blade construction, increasing thickness h very quickly makes it stiffer – i.e. stiffness grows as the third power of thickness (as originally posted 05/22/2013 at 7:24am, paragraph 6). " So it appear you too grasp the differing divergence of a linear vs 3rd-order polynomial function. In practice most TT blade woods don't differ much anyway: most surface species are ~10-13 GPa, and inner ones are in similar relative range. > As I remember, that formula also included structural terms that let us understand the connection between the mode frequencies and how the layers of the blade contributed. Just because a function contains some of the right variables and seems to go in the right direction doesn't mean it's necessarily accurate. You might recall straight up stiffness contains the same variables without some of the drawbacks of frequency. You might also recall that a relative simple transform to any of these "kind of right" unbounded indicators make them significantly more right. In the real world wood density/hardness tends to vary and it's usually not possible to measure frequency before buying anyway, so in practice considering overall thickness with some compensation for any usual characteristic gets maybe 80% accurate results for very little effort. I seriously doubt more complicated metrics for standard blade is more than 10% better, and in any case probably less so than just pumping the rather trivial aforementioned transform if there are significant differences in thickness/rigidity. Edited by AgentHEX - 12/21/2014 at 5:19am |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/21/2014 at 4:47am Posted: 12/21/2014 at 4:47am |

|

In general most "technical analysis" in TT tends to be post hoc rationalization of player's observations/beliefs. Ie. I play better with this vs that so this must be superior due to x, y, z. In reality by far the greatest variable in play is the person holding the racket. For example, the "throw" of a shot is mostly determined by the stroke itself and not the equipment. A fast (relative to ball) and high angle of attack will simply throw higher. Players with solid form only need to make rather minor adjustments for whatever differences in blade/rubber which are in same ballpark. In this case of spin vs speed, the spin is what higher level players use to keep the ball down and provide some extra kick off the table; meaning you need enough of it to keep it in play, a factor which you the player control through varying angle of attack, speed, and blade ange. A slower blade makes high throw high spin shots easier to learn, which is by far the most important factor for less than high level amateurs. There's near order of magnitude difference in physical efficiency nevermind efficacy between ~1500 level brush loopers and elite loop drivers, so while minor tradeoffs in the tools might be technically interesting it's kind of trite in the grand scheme of things. Edited by AgentHEX - 12/21/2014 at 4:54am |

||

|

||

JRSDallas

Silver Member

Joined: 09/03/2005 Location: USA Status: Offline Points: 585 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/22/2014 at 4:12am Posted: 12/22/2014 at 4:12am |

|

1. You accuse that - "I am assuming frequency is directly correlated which is very much in question". Well since you have by omission left me with my choice of what frequency is correlated with, I hereby claim that frequency is directly correlated with frequency, i.e. f = f. I win. 2. Your parenthetic statement (they certainly aren’t with respect to size, and who knows what else) says you claim that (frequency) is not correlated with blade size or other physical parameters. I disagree and claim that for a symmetrically laminate cantilevered beam (as a 1-D approximation to a table tennis blade face) exhibiting vibration mode frequencies fn , THAT frequency is in fact correlated with the causal function: Blade frequency of vibration mode n vs blade stiffness: E k is the modulus of the kth lamina relative to the midplane I k is the moment of inertia of the kth laminate layer relative to the midplane, where I k = b hk3/12 + bhk dk 2 dk is the distance from the midplane of the laminate beam to the center of the kth laminate ply where k = 1 to N. hk is the thickness of the kth laminate layer dk is the distance from the midplane to the center of the kth ply b is the width of every laminate layer L is the length of the every laminate layer N is the number of layers in the laminate beam n is an integer identifying specific modes of vibration where n = 1, 2, 3….. r is the mean density of the laminate beam A is the area of the end face of the laminate beam, wher A = width b * sum of hk, for k= 1 to N

Further the above correlation is causally based on the physical parameters of blade size (parameters length L, width b, cross section face area A), and other physical parameters (density r, Young’s modulus E, Moment of Area I ). Since this relationship was derived from the (1) accepted theory of beams, and (2) accepted rules for mathematical manipulation, it is widely accepted as correct as it stands. Finally, as this is the same claim I made in 2008 when I originally posted this derivation and in 2013 when I reposted it, the evidence suggests that your understanding correlates with unskilled. I win again. You of course are free to contest this by showing that the theory of beams is wrong (to first order, and not at some limit of relativistic speeds or other silly flapping about), or show that the mathematical solution to the differential equation is in substantially in error. I won’t hold my breath.

Please also refrain from using Wolfram Alpha to pull up some non-physical function (as you did earlier in this thread) to argue that it is a better predictor. We all know that the declining number of pirates is strongly negatively correlated with the increase in global temperatures. Of course the pirate correlation IS true, but only the unskilled believe it to be causal. 3. HEX said “To elaborate further, if what you're claiming about the relative significant of surface vs inner plies is true it should certainly show up in this category of theories as some relative weighted factor with respect to distance from center (then integrated over the thickness of the plate).” Well lets look….….yes the contribution of plies that are displaced from the plywood

mid-plane correctly does show up as a distance squared weighting factor per

the Parallel Axis theorem, and by golly the weighing has been there since the

original posting of this thread in 2008, and since this MyTT.net reposting in

2013. Maybe you should get your eyes checked? The fact that you could not see this weighting until I said it in words suggests that you haven’t (can’t?) follow the math that was presented in detail. Further, since even now you are only looking for “some weighting factor”, it shows that you don’t know the physics that the math is describing. Now you admitted as much earlier in this thread, you said when you did not understand how I was using the parallel axis theorem to calculate the area moment of inertia I of the laminate beam in the first place. Admittedly, what I have not expected is how adamant you are in claiming I am wrong, when you actually don’t see what it written. So…..just to be clear…..your claim that I was not correct about the impact of ply placement is and has been pointless from the beginning. I win this one as well – Just saying what’s true. To assist you, the detail of how the area moment of inertia for the kth lamination of the laminate beam is calculated below. The correct weighting of course is there as it was in the beginning and ever will be. Finally, I’ve just tonight discovered an article in Procedia Engineering, Volume 34, 2012, Pages 604–609, ENGINEERING OF SPORT CONFERENCE 2012 that addresses the same topic that my original 2008 thread addressed. The abstract clearly includes the approach I took in my original 2008 work. Makes me feel pretty damn good that I took this same path six years ahead of them. -- I think this counts as another win for me. Just sayin’. Vibro-acoustic of table tennis rackets at ball impact: influence of the blade plywood composition Lionel Manina, Florian Gaberta, Marc Poggib, Nicolas Havardc Abstract - The performances of a table tennis racket can be qualified with several adjectives like: fast, slow, stiff, adhesive, controllable, etc. These qualifications are subjective since they are relative to the sensory analysis made by each player. It appears that the noise produced at the ball impact on a racket has a great influence on the opinion that a player can give about a racket. Moreover, the sound emitted at the stroke can be appreciated differently among several players. Hence a good sound may give a positive a priori to the player racket appreciation. The work presented first demonstrates the correlation between the acoustic frequency spectrum and the vibration frequency spectrum of a racket following the ball impact. The analysis is first performed on the racket blades without rubbers glued on. The vibration modes that produce the sound at the ball impact were identified experimentally. It is shown that there are two essential modes responsible of the sound emitted. In second, comparisons were made between several rackets composed of different composite plywoods. Their influence on the sound emitted is shown experimentally. Indeed, depending on the wood essences of the different plies, their thickness and their fibers relative orientation the sound produced will be different. Then the influence of the rubbers glued on both blade sides is studied. The vibration modes are the same but the frequencies are lower. The sound can be qualified as sharp, long, clear, deep, hollow, and plain. Some correlations with the player appreciations are made. References [1] Y. Kawazoe, D. Suzuki - Prediction of Table Tennis Racket Restitution Performance Based on the Impact Analysis, Theoretical and Applied Mechanics Japan, 52 (2003), pp. 163–174 [2] K. Tienfenbacher, A. Durey - The impact of the table tennis ball on the racket, Int. Journal of Table Tennis sciences, 2 (1994), p. 1994 4. Earlier in this thread, you said that the dwell time of a TT ball bounce on a racket was 1ms and that a supersonic TT ball impact on a hard bat and a molecular (hard sphere) model of a TT ball bounce proved this. You are adamant about 1ms and have used it to argue against popular belief that blade flex and recovery contributes to catapulting the ball off the racket. I said I thought that dwell was 3 – 5 msec, but as I could not find my original source that perhaps my memory of an article I saw in 2008 was wrong. I have now found the article

I saw in 2008. What is more, it shows

table tennis ball on racket contact times (dwell) of 4-5 ms (see Fig 15

below), a marginal 400% to 500% longer than the forcefully claimed 1ms. The

article is in: Science and racket sports

III : the proceedings of the Eighth International Table Tennis Federation

Sports Science Congress and the Third World Congress of Science and Racket

Sports / Published London ; Routledge, 2004. Y.

Kawazoe and D. Suzuki -- Characterization of table tennis racket and sandwich

rubbers (Tamasu Corporation aka Butterfly ).

Selected excerpt below – Just saying.

BTW – These Butterfly research guys also physically characterized the BISIDE racket they used in the experiment. Not too surprisingly, one of the few parameters they felt was important to record was the racket frequency. – Again, just sayin’

5. > HEX talks

plate theory but does not recognize that the plate theory equation he has seen

assumes an isotropic and homogeneous material Yes really really Hex and I do it because I made this exact point much earlier in this thread, (originally in 2008 six years ahead of you) and that original point is: Now because you cannot admit that you have read it, you’ve been claiming that I am ignoring parameters such as blade size (but blade size = A *L so that opinion of yours is now proven false) and blade mass, length, modulus E, area moment of inertia. You keep repeating this, while willfully ignoring the fact that the parameters are in the equation. You also willfully ignore that as I derived it so would I know they were there, and since I have written them down, that I have not ignored them. Since you could not see the elephant in the room, I adopted your strategy. I thought you would be upset if I adopted the same argument against you as you were making against me – a dose of your own medicine and overdue. You ignored my results and then claimed that parts of it were yours. You’ve just complaining that I have unfairly adopted your point that stiffness E*I and thickness matters. Wow……..I am underwhelmed. Yes, stiffness and size and mass and area moment of inertia and thickness are clearly in my equation above. Further, the relationship above is much more explicit and carefully thought through than the verbal pondering you have presented (of course you actually have not presented anything other than words). SO…to recap, I am making the exact same point you have made, but its my right since I was the first to make it, and I did it in writing years before you showed up. I can’t claim a win here since you were never actually in the point. Of course all of this is simple engineering and well understood by many. BTW – Plate theory also generates mode frequencies with a very similar results. Maybe you could take some time and derive that for us.

6. ) JRSDallas said "Finally, for any given blade

construction, increasing thickness h very quickly makes it stiffer – i.e.

stiffness grows as the third power of thickness (as originally posted

05/22/2013 at 7:24am, paragraph 6). " Gee I guess so. I prefer composites because of the wider design range they offer. Recently I was surprised by the calculated effect of a hard wood outer ply overwhelming the stiffness contribution from carbon layer below it. I could just say that all 7mm blades play the same, but I have had too many and I know they don’t.

There you go again talking about unbounded indicators. WWWWOOOOOOUUUUU there must be some sort of deep spooky insight or dark magic danger from an unbound indicator akin to the role that prime numbers density plays in the density of quantum chaos energy levels or in Bessell function eigen modes – Oh my god frequency again! Nu Nu Nu Nu…. Nu Nu Nu Nu…. It is up to the reader to apply some intelligence as to when a difference of frequency is relevant to their task of comparing the relative stiffness of two blades. In every case, I have presented the use of frequency as a discriminator in those terms. It is a very sensitive discriminator and a reasonable tool. Further, I took pains to point out the variability in wood samples even when building many copies of the exact same blade. Yes, most of us know that blade to blade differences for

even the same model are large so yes, buying any blade is a crap shoot even

after you account for thickness, and compensating for unusual characteristics.

Touching the blade and even better playing with it are the best

indicators. But…….don’t forget that the

thread topic is to understand the playing characteristics of wood. SO…..the goal should be to take the effort

to actually try to understand rather than argue that it isn’t worth bothering to

understand. Everyone can argue that they will never use some topic or other that they had to study in school. I would argue that knowledge for knowledge’s sake creates both a rich internal life and improves the fabric through which we see the world. Edited by JRSDallas - 12/22/2014 at 9:53am |

||

|

Galaxy T1 89 gm

FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/22/2014 at 5:29am Posted: 12/22/2014 at 5:29am |

|

|

Please try to understand what is being said before going off. I did not make the statements above nor below without careful consideration and any possible error will not be trivial. OTOH the error in that frequency equation rather is.

> Well since you have by omission left me with my choice of what frequency is correlated with, I hereby claim that frequency is directly correlated with frequency Your general assertion through this thread and reinforced just above is that frequency is a good first order approximation of speed. This is not in dispute. What is in contention is the quality of approximation and its exclusivity to frequency, namely that other simple "indicators" are similarly valid (and flawed in their individual ways). I don't believe you're disputing this, or at least haven't done so above. > Your parenthetic statement (they certainly aren’t with respect to size, and who knows what else) says you claim that (frequency) is not correlated with blade size or other physical parameters. You misunderstood that statement since I claimed the exact opposite, and this claim is exactly the reason why frequency is particularly flawed as mentioned at least twice above: speed will not vary significantly with size, as better predicted by, say, stiffness rather than frequency. I noted this to punctuated these particular flaws. > yes the contribution of plies that are displaced from the plywood mid-plane do correctly does show up as a distance squared weighting factor per the Parallel Axis theorem > Now you admitted as much earlier in this thread, you said when you did not understand how I was using the parallel axis theorem to calculate the area moment of inertia I of the laminate beam in the first place. First of all, please consider that I was trying to be polite. In hindsight this was a poor idea. The error is actually pretty obvious and the reason it evaded capture only slightly less so. I've detailed above exactly why the use of Parallel Axis theorem here is wrong. More briefly, note that it is by definition calculated from the center of mass to the center of rotation. By your own assumptions for the beam equation, the center of rotation is around the "end" of the blade (ie the fixed neck point), which is certainly reasonable. But note that the distance from that point/axis to blade center of mass is quite a bit further and in any case perpendicular to the few mm the plies are shifted. Before being dismissive, draw out the diagram with both axis specified, it's not hard to see the problem and I would expect any first year physics student to be able to do it. The way Parallel Axis is being used in your freq equation is a fundamental error in the basic geometry involved. The specific numeric illustration a few posts back should provide additional illumination. The reason why this clear error is not evident (ie blows up the results) is that the terms involved are rather small as mentioned. However, also as mentioned it's visible how this came to be in the first place: you're trying to account for the intuition that the outer plies have more impact than inner ones, and way how parallel axis seems to work out (with its wrong application) assuages that concern since bigger numbers are multiplied for plies further out. This intuition is not in dispute given you just repeated it in another post above. The weighing is however completely wrong and certainly not the weighing in actually plate equations I was referring to. To tie this all together, consider a blade with a hard surface on only one side (and the other missing or whatever). Note your equation is agnostic to which side the impact is on; surely they differ if surface layers matter, which rather ruins that "greater surface effect" illusion the equation is supposed to illustrate. Again, to provide some perspective, a careful particle sim of the whole collision would probably show some surface effect, but this has to do with the peculiarities of how internals of solid materials work, and nothing to do with rotational inertia. Analysis of such matters are well beyond what can be provided by simple clean equations. > Please also refrain from using Wolfram Alpha to pull up some non-physical function (as you did earlier in this thread) to argue that it is a better predictor. We all know that the declining number of pirates is strongly negatively correlated with the increase in global temperatures. I'm not sure how this is supposed to make any sense. My Wolfram Alpha plot is just how any realistic speed vs (thickness, freq, etc) plot must necessary look like. If that's not clear, please consider what bounded vs unbounded means again. Any unbounded method of determining it is necessarily wrong without some attempt to massage the math into a sane shape. This is basic physical modeling 101. Edited by AgentHEX - 12/22/2014 at 6:52am |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12/22/2014 at 5:39am Posted: 12/22/2014 at 5:39am |

|

|

> I have now found the article

I saw in 2008. What is more, it shows

table tennis ball on racket contact times (dwell) of 4-5 ms (see Fig 15

below), a marginal 400% to 500% longer than the forcefully claimed 1ms.

As a physicist I trust you can do a basic mechanics calc. Use the parameters of 10-20m/s v-initial, a displacement of 1-2mm at most, and force akin to a spring; then see if that time is anywhere near possible. If it is, these guys should get a Nobel for discovering obviously non-newtonian effects on the face of a TT racket. Since there's no link to the rest of the article, I'll leave it an exercise to you to find where their error lies. The main problem here seems to be that you're not willing to do the most trivial validation of basic assumptions even after it's been pointed out. (For the visual learner, there's at least two ~1000fps videos verifying this basic physics) Edited by AgentHEX - 12/22/2014 at 5:52am |

||

|

||

Post Reply

|

Page <1234> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

|

Forum Home | Go to the Forums | Forum Help | Disclaimer

MyTableTennis.NET is the trading name of Alex Table Tennis Ltd. |