Blade Performance Vs Wood Type and Design

Printed From: Alex Table Tennis - MyTableTennis.NET

Category: Equipment

Forum Name: Equipment

Forum Description: Share your experience and discussions about table tennis equipments.

Moderator: haggisv

Assistant Moderators: position available

URL: http://mytabletennis.net/forum/forum_posts.asp?TID=60725

Printed Date: 04/18/2024 at 11:27am

Software Version: Web Wiz Forums 12.01 - http://www.webwizforums.com

Topic: Blade Performance Vs Wood Type and Design

Posted By: JRSDallas

Subject: Blade Performance Vs Wood Type and Design

Date Posted: 05/22/2013 at 7:20am

|

This thread is a reposting of a HOF thread that originally was on Dennis' Table Tennis World (DTTW) under the title " http://www.tabletennis.gr/Table-Tennis-Forum/13-Hall-of-Fame/118552-Playing-characteristics-of-blade-materials.html - Playing characteristics of blade materials ". This reposting only includes the initial question and selected later questions and posts I wrote to answer them. The original thread had 16,870 views but it got scrambled when DTTW moved to a new database and I was not able to fix it. If after completing this reconstruction, if I discover that I can fix the DTTW thread, then I will.

Question: "..it would be useful to a lot of people on this forum to know the playing characteristics of each type of blade material."

Answer:

Part I - Engineering Properties of wood

Part II - Design Issues

Part III - Beam Theory (Don't sweat the math - results and concepts are what matter)

Part IV - Comparing Calculations for Different Blades

Part V - Finite Element Analysis Results

Part VI - Empirical Measurements

------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Replies:

Posted By: JRSDallas

Date Posted: 05/22/2013 at 7:22am

|

Blade Performance Vs Wood Type and Design PART I - Engineering Properties of Wood

The question was about how different woods impact blade performance but there is no simple answer. Still, here is an answer on the topic of materials and blade design. We will be addressing normal sized table tennis blades that meet ITTF standards (at least 85% of the thickness is made up of wood), and normal weight ranges which roughly are:

Blade: < 80 grams light, 80- 90 grams medium, 91+ grams heavy Racket: < 175 grams light, 175 – 188 grams medium, 189+ grams heavy Many factors effect blade performance: mass, bending frequency, damping, swing weight, and surface layer hardness. All of these factors also have to be matched to your personal preferences and style of play. Of these factors, only mass is ever directly listed in catalogs. Surface layer hardness is alluded to as soft, medium or hard feel. Bending frequency and damping are mixed together and alluded to as defensive (low frequency, higher damping), all-round (medium frequency, unknown damping), offensive (high frequency, low damping). When I started thinking about building a custom blade, I started with a table of wood engineering properties on about 200 domestic and imported species commercially available that the U.S. I then calculated a simple figure of merit composed of the Modulus of Elasticity (in Mpa) divided by the Specific Gravity (a measure of density) to highlight woods that were elastic and light in the hope that this would identify species that could be good for a table tennis blade. My results included many woods that are found in table tennis blades so my approach seemed pretty good! A larger database would probably turn up additional candidate woods.

The identified woods are good candidates for a single ply blade, so the next step is to design a blade face and handle area so that a total area is known. Once we know the area, we can then use this and the density (specific gravity) to estimate how thick we can make our single ply before it gets too heavy to use. We need to also reserve 10 - 15 grams more for the handle.

Now if we want to figure out how stiff we want to make the blade we either have to know how to calculate what stiffness we want (hard) or we just have to make one and see how it feels. If it plays too stiff, then make a second one thinner, too flexible, then make the next one thicker. Once you learn what thickness you like in a blade with a given wood, (thickness is the biggest factor in stiffness), you’ll probably like the same thickness in most every wood with similar engineering properties. Since none of the listed soft woods are dramatically different from each other, the solutions to what a good feeling single ply blade out of any of them will end up being pretty close to each other. Now as table tennis players, we already know that most single ply blades are 8 - 10 mm thick Hinoki. Some are made from Port-Oxford Cedar, or other cedars or spruces or other soft woods but they all seem to end up being 8 – 10 mm thick. This is because each of the these softwood species exhibit similar engineering properties. This is why you don’t see anyone posting how great their single ply 5 mm fir single ply is and how it hits faster than a Schlager Carbon! But what if I want a hard stiff blade for hitting but I don’t’ want a blade 10 mm thick? We also know that most table tennis blades are 5 ply or 7 ply and that many have synthetic layers (carbon, carbon-aramid, etc) or are even more complex. Why? The answer to these is based on beam theory and how material selection and distribution through a blade establishes the bending properties (defined as the second moment of inertia) of the blade. These more complex construction techniques let us make the blade stiffer and/or more uniform in its bending properties while keeping its mass or thickness the same or even less than could ever be achieved with a single ply of wood.

I’ll address this in a subsequent post………… ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Posted By: JRSDallas

Date Posted: 05/22/2013 at 7:24am

|

Blade Performance Vs Wood Type and Design PART II - Design Issues In my earlier post I said nobody posts about their 5 mm single ply blade and one reason they don’t is because such blades are easy to break in play. Wood’s physical properties are non-isotropic, i.e. they are not the same in every direction. If you look at pictures of a single ply blade, you always see parallel grain lines running the length of the blade from the handle to the tip. This aligns the strongest axis of the wood with the bending that occurs during table tennis. If instead you were to grab the single ply blade by its two sides edges and bend it, the wood is much weaker when bent on this axis and it can easily split along one of the grain lines. You might even be able to snap it with your hands. So lets we want to use a particular wood but we also want to make its bending properties from side to side the same as from handle to tip. This is done by making plywood from two or more thinner layers of the wood glued together with the grain directions placed at an angle with respect to each other. If we have three layers, then we glue them at 60 degrees to get the most uniform bending in every axis (and so on). We could use smaller angles to retain greater bending strength in a preferred direction while still improving strength in the perpendicular direction. Our plywood will have more uniform bending properties but it won’t be as stiff as the original wood was in its strongest direction since we’ve distributed the total stiffness in other directions as well. The glue type, solids content, and pressure also matter when making plywood as the glue joint also has to flex when the plywood flexes. Hide glue (made from boiled animal tendons) is the traditional wood glue used for centuries in furniture, musical instruments and – custom table tennis blades! Few blades today however are made with hide glue. Hide glues are flexible and a hide glue joint can be fully undone and repaired with steam heat. Modern glues such as PVA (white or yellow wood glues) are rubbery synthetic polymers that are good for porous materials such as wood and paper and they are commonly used in making books because of their flexibility. PVA glue and epoxies dominate table tennis blade manufacturing today. These also can be very good glues and are very durable. Now lets assume we want to make a 4 mm thick three layer plywood out of a harder wood such as black walnut, with a blade face and handle total area 230 cm^2 (Butterfly Amultart size). Since black walnut has a specific gravity of 0.55 our blade’s expected total weight (less handle pieces) is 0.55 grams/cm^3 x 230 cm^2 x 0.4 cm = 50.6 grams. Now we add 24 grams for a walnut wood handle, plus 1.3 gram of glue per ply and we arrive at a total weight (in theory) of 77 grams. Now, when making plywood, one needs a vacuum press and equipment to evenly sand down the layers to the needed thickness. This gets more expensive than just buying and trying blades but it lets you build blades you can’t buy, but this cuts both ways since you can also buy blades you can’t build. If we play with our pretty thin blade, it should feel hard on ball contact because black walnut has a side hardness of 4500 N (compared to Port-Oxford Cedar which has a side hardness of 2800 N), but since it is only 4mm thick we also might find that the blade itself is more flexible than we expect. This will be further exacerbated since the wood’s maximum stiffness has been reduced by the averaging that occurred when making it into plywood! So, if we had picked black walnut in order to make a hitters blade, and assuming we are finding it too flexible for hitting, the best path to making it stiffer is to make it thicker. A key mechanical engineering property of uniform materials (such as our plywood) is that stiffness increases with the third power of the thickness. So if we increase our thickness from 4mm to 5mm, (i.e. a 25% increase in thickness) we end up with a 53/43 = 125/64 = 195% increase in stiffness. Unfortunately, as you can see that with adding only 1 mm more thickness, we’ve gone from a medium 77 grams to a pretty heavy 96 grams and we don’t even know if were stiff enough yet (of course we could very well already be too stiff, but we’re the main point is that working with hard wood only gives you a very short thickness range to work with before you get too heavy. This is why you don’t see many table tennis blades made from hardwoods – hey do exist but they are rare. As an example, look how wide the various usable thicknesses are for Sitka Spruce are and how much the stiffness varies over that thickness range compared to black walnut. The walnut gets too heavy before its stiffness has even doubled.

Remember stiffness increases as the third power of thickness… I haven’t gotten to beam theory yet other than the point on stiffness being primarily driven by beam thickness, but I’m getting there. I’ll have another post later…… ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Posted By: JRSDallas

Date Posted: 05/22/2013 at 7:47am

|

Blade Performance Vs Wood Type and Other Design Issues: Part III -- BEAM THEORY

This post is long and has a lot of basic beam theory that I have been teaching myself at the same time that I’ve been writing. So…without further delay…..

Solid mechanics uses non-linear matrix models to describe physical behavior but this math is often simplified into linear models, to ease computation. Beam Theory is one such simplification. However, non-linear models are becoming more common and easier to work with due to computers. Most real world physical phenomena start off linear during small changes but become non-linear as changes grow. Common types of behavior under deformation are:

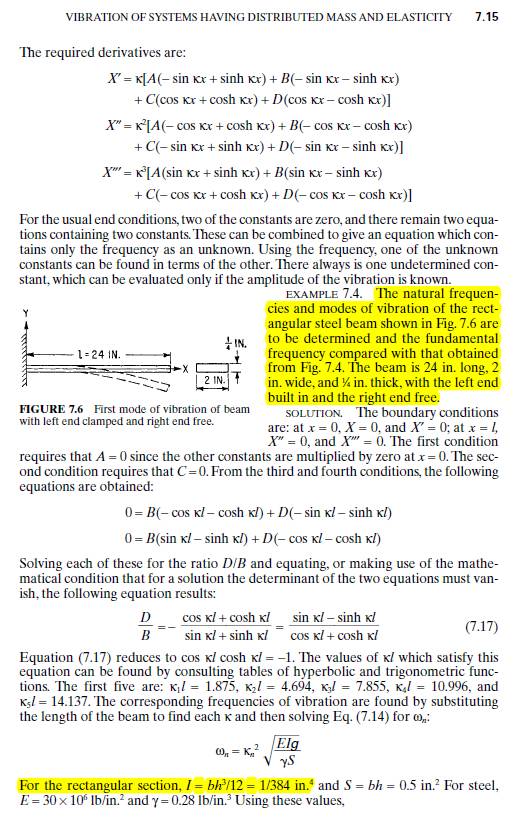

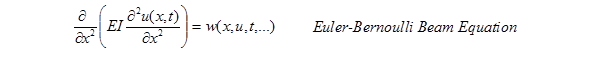

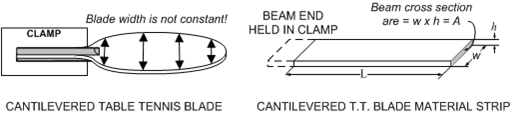

Computer Modeling Tools: The best way to explore this topic is to model the table tennis blades within a Finite Element Analysis program capable of dealing with composite material construction, dynamic analysis and impact deformations. With such software one could model various table tennis blades, calculate their different frequency responses and bending modes and even cover them with inverted rubber and sponge hardness to study sponge hardness versus blade hardness, how striking method and blade frequency effects power and spin creation and so on. Unfortunately, I do not have such software and though I am trying to get some, actually getting it, learning to use it and finally building an accurate physical model will take months of effort. If I am successful on this longer term path, I will be sure to come back. Still, no one can build a good model without knowing the theory first. So lets start with the Euler-Bernoulli Beam Equation (first written around 1750) for the elastic bending of a 1-dimensional beam. This 4th order differential equation describes the relationship between a beam's deflection u and the applied load w.  In this equation, the deflection at each point x, is the function u = u(x,t). The load at point x, is w = w(x,u,t,….) where w can be function of x, u, time, or other variables. E is the http://en.wikipedia.org/wiki/Elastic_modulus - of the beam material and this is the same as the “modulus of elasticity" that we saw with wood species earlier. I, the http://en.wikipedia.org/wiki/Second_moment_of_area - , and this is a value that accounts for how the beam’s cross section shape resists bending. We’ll come back to E and I later. To simplify our math (by a lot), we will mentally reshape our table tennis blade into 1”x7” inch strip with one end clamped into a vice so that a 1”x6” inch blade face strip sticks out and is free to vibrate. This gives us a classic cantilever beam built up as a single ply, a 5 ply, a carbon blade of thickness ”h”. Our simplifications make u = u(x), http://en.wikipedia.org/wiki/Stiffness - - E - I constant, and our beam mass density r, constant. We now pick the load w(t) so that we start with the beam equation for a vibrating cantilever:

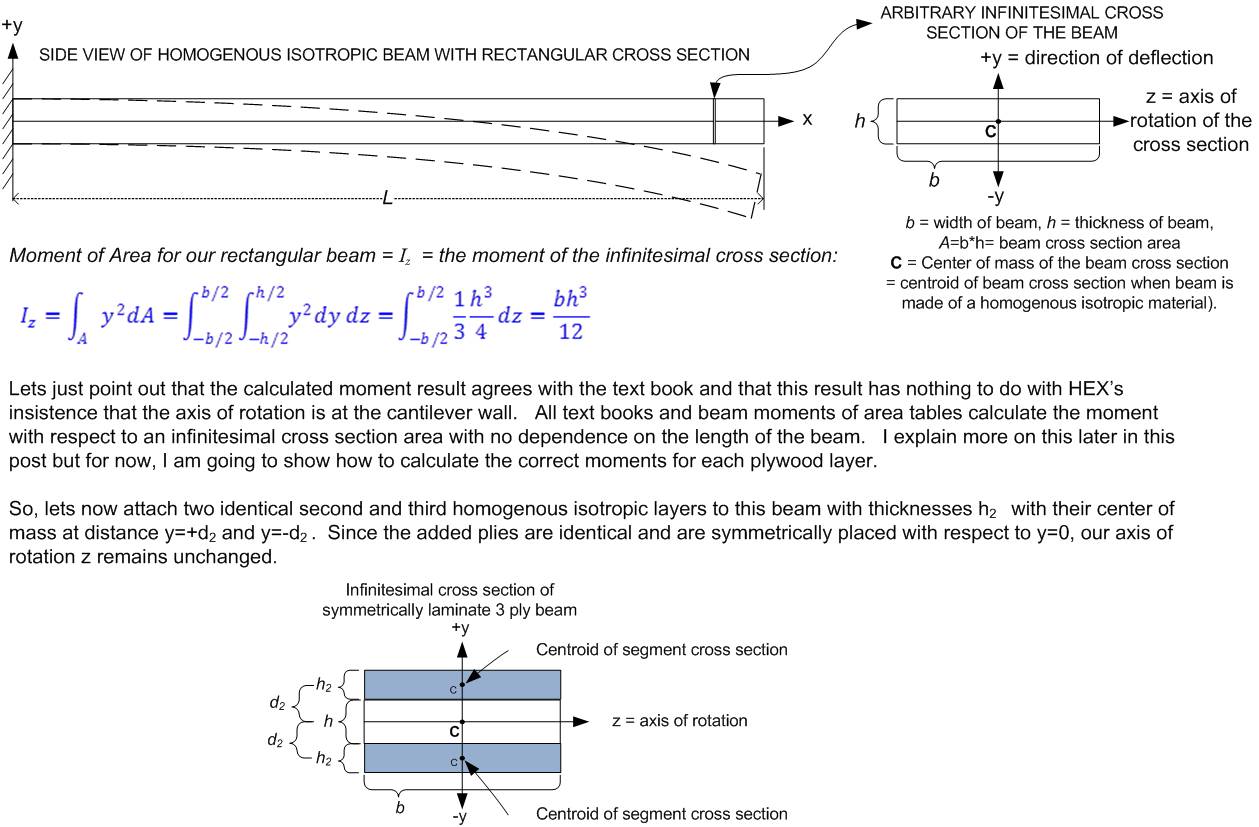

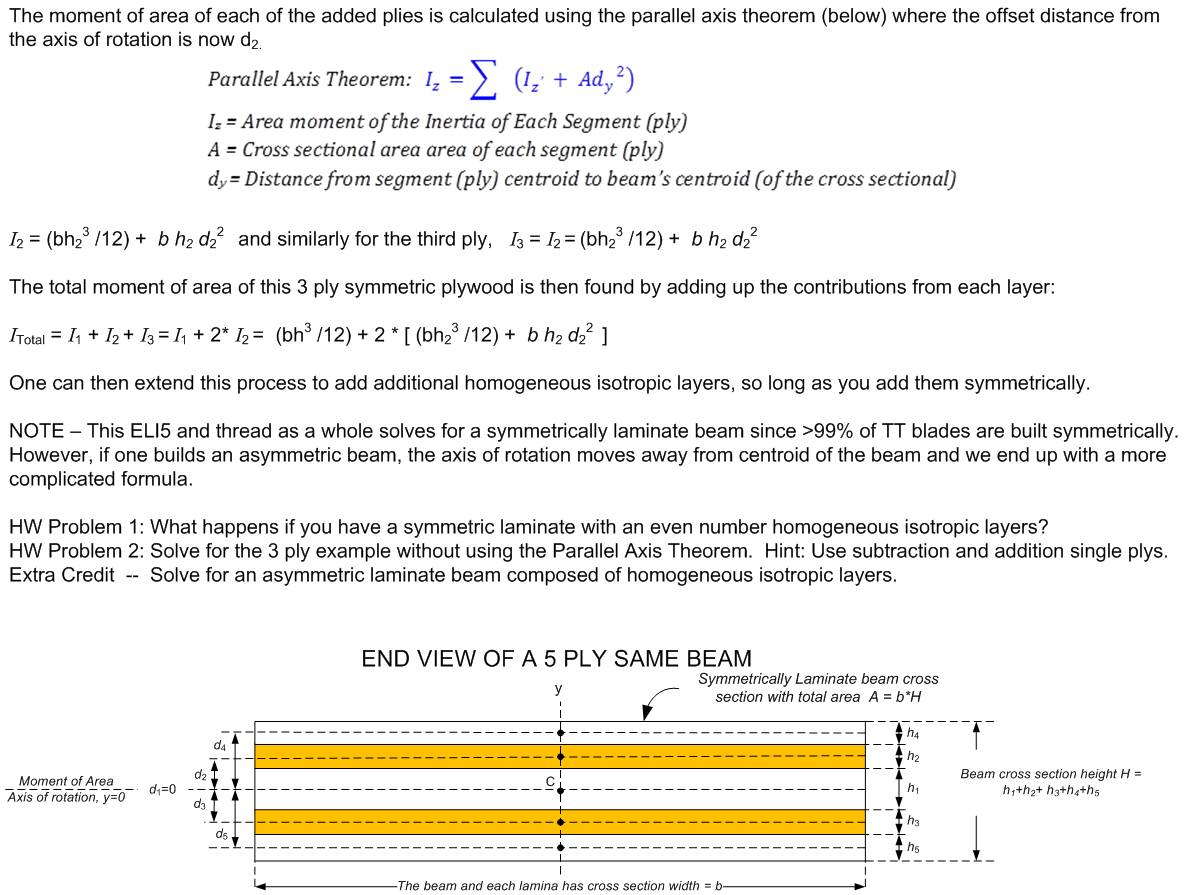

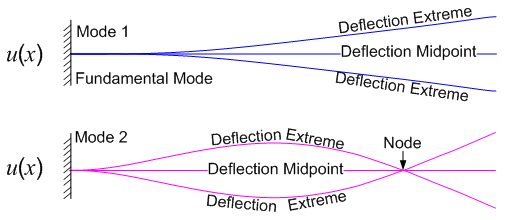

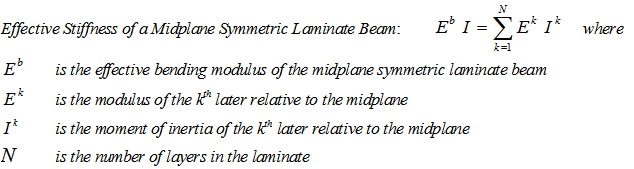

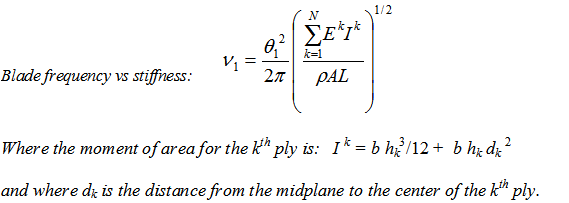

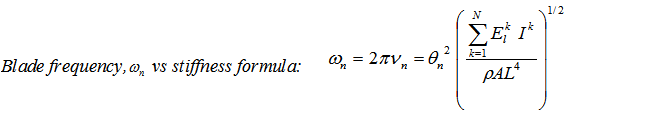

The following graphs show our cantilevered blade vibrating in a single mode. Interestingly, at the mid-point of every vibration mode, the blade returns to flat.  When we play, our hands feel the blade vibrations caused by the ball impact, (i.e. we feel the vibrations of our cantilever). When we hit the ball on the sweet spot, we mainly feel the dwell and catapult from the mode n = 1 vibration, the fundamental frequency of the blade. When the blade is soft or stiff, we feel that softness or stiffness as more or less dwell. More dwell means a lower mode 1 frequency while less dwell means a higher mode 1 frequency and a stiffer blade. Besides the mode 1 behavior we normally feel when playing, we sometimes hit the ball off center. When we hit the ball hard and off center, we will also feel some higher frequency vibrations due to higher frequency vibration modes being excited by the higher energy impact. Most of us have had the experience of hitting a ball hard but missing the sweet spot of a racket or bat or club. When this happens, the impact drives a lot of energy into the higher frequency modes of the bat or club. That’s why your hands sting when you miss hit a baseball or a golf ball. High frequency modes start vibrating and your hands damp it out. The last thing we need to do now is learn at how to calculate E and I for layered beams. We didn’t have to worry about how to do this for our single ply blades but we have to worry about it for multi-ply blades. When using layered beams in which the plies are oriented symmetrically about the midplane and where the orthotropic axes of material symmetry in each ply are (ex. the wood grain is) parallel to the beam edges, can be analyzed by via classical beam theory if the bending stiffness EI is replaced by the Effective Stiffness of the beam.  Now the moment of inertia I for a beam with rectangular cross section of width b and height h, is given by I = b h3/12. When this cross section is not at the center of the beam (such as will be the case with all but the center ply in our laminate table tennis blade), the Parallel Axis Theorem lets us calculate the moment of Inertia of each ply. Thus the moment of inertia I k for the kth ply is then: I k = b h3/12 + bh d 2 where d is the distance from the midplane to the center of the kth ply. We can now update our frequency versus stiffness relationship to account for the effective stiffness of a laminate blade so that we are finally ready to calculate how stiffness and frequency behavior is affected by material selection, thickness and construction techniques. Our frequency vs stiffness equation for multilayer construction blades is:

Ok. There is a good bit we can learn about blade cross-section design by studying this formula and even more by calculating how different blade designs behave. Even with all this work though, we’ve only studied a strip of wood constructed like a blade. A real blade has a larger oval face and a throat that also greatly affects its stiffness and frequency behavior. Getting a handle on this requires numerical modeling.

This has been a long hard post, so I’ll save the looking and calculating for the next post….. I’ll be back with Part IV…….. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 05/22/2013 at 7:52am

|

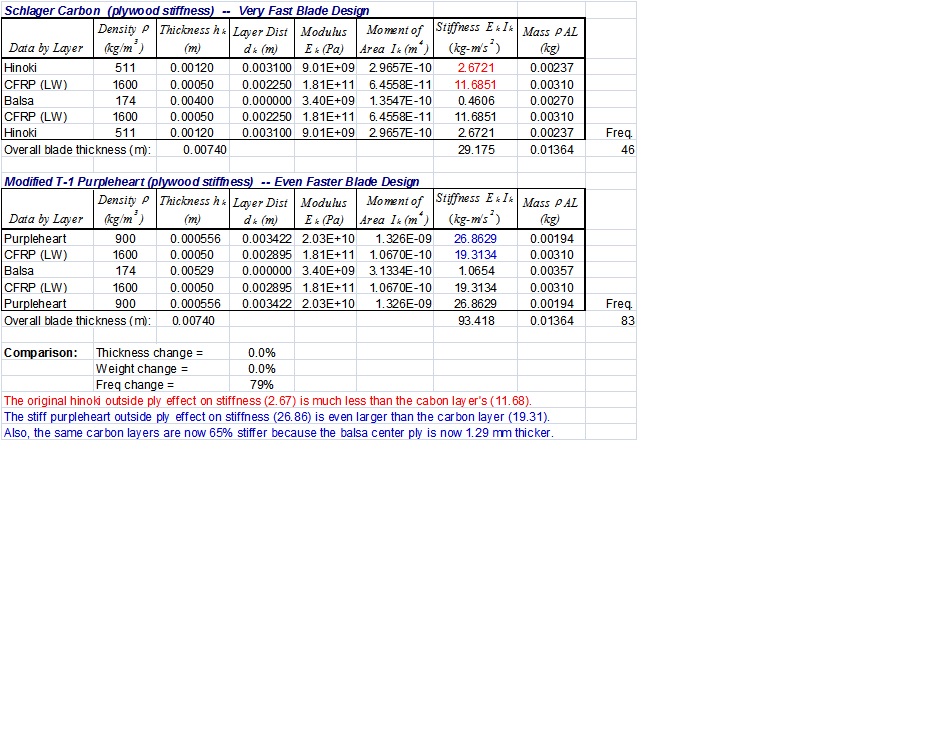

Blade Performance Vs Wood Type and Other Design Issues: PART IV -- COMPARING CALCULATIONS FOR DIFFERENT BLADES

Given the robust discussion that followed the last post, I can see that people are hoping for something a bit easier to digest…. This should help. I’ve used the formulas that were derived in the last post to calculate the behavior of various blades based on their different constructions. Now in this post, I am talking about the cantilevers as our surrogate model for examining relative performance between different blade constructions. Also, I have calculated the mass of the cantilever, the stiffness of the cantilever and n1, the frequency of vibration of mode 1 of the cantilever . The frequency is the true measure of how fast the “blade” is.

In the table below is some of the engineering data that I showed in the Part I post, and I’ve also added some engineering data for some more woods and some carbon fibers. All of the calculations pull from the data below. I don’t use all of it but I do calculate 11 different types of blades.

Recalling the blade frequency vs stiffness, but expressed in frequency n (cycles/sec = Hz) rather than angular frequency w (radians/sec). Most of us are familiar with frequency in Hz as this represents the pitch that you hear with your ear.

Now it has been pointed out that you can’t always calculate everything and that’s true. More importantly, not every piece of wood is the same even if it is from the same species and area. For example, I don’t think I was able to find good data for Hinoki, and it certainly does not appear to represent the properties of Kiso Hinoki as the Port-Oxford Cedar seemed to out perform the Hinoki fairly easily. Hinoki has a pretty wide range of density so this is to be expected of it (and this is to be expected of all woods). Similarly, all carbon fibers are not the same, and which types of carbon fibers you pick and if you use them as a woven cloth or as layers of uniaxial fibers at different angles strongly effects your results. You’ll see in my last blade calculation where I calculate for a Schlager ULC Carbon. This is a Schlager Carbon construction where I have instead aligned all of the uniaxial carbon layers with the axis of the cantilever. This orientation really increases the stiffness and frequency while reducing the normally larger sweet spot size of a carbon blade to that of a wood blade. This table shows the frequency (speed) results for a lot of different blades.

You can see from the Hinoki single ply results that stiffness does increase as the 3rd power of thickness. Ex. 103 / 83 x 9.764 = 19.0625, i.e. very close to 19.071. HOWEVER, stiffness does not equal SPEED, it contributes to speed. FREQUENCY however is directly tied to SPEED but none of the blade manufacturers measure the frequency of their blades. You can listen to the frequency and pick the faster blade by listening for the higher pitch. Here are the rest of the blade calculations I’ve done:

OK that should wrap up Part IV…. The calculations do show that changing design does change frequency behavior and therefore blade speed. There is of course other things to worry about like the size of the sweet spot and touch at low speeds but that as I said in the beginning, all of this is very complicated and just getting even a basic handle on the simple parameter of blade speed (frequency) has taken some work. In any case, while there is more to consider perhaps this is enough…. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Posted By: JRSDallas

Date Posted: 05/22/2013 at 7:53am

|

Part V -- TO COME But first a response to a post about not being able to have perfect information and more importantly (from my viewpoint anyway) the value of having a deeper theoretical understanding, and an appreciation for the issue of unit-to-unit variation.

A poster cautions: "Be careful when applying purely mathematical considerations to wooden materials. Pythagoras tried to do that to stringed instruments. However, every stringed instrument using Pythagorean tuning has a few dead or flat notes, even holding "perfect" tune. Feel is much the same way, defying quantification." Related answer in response to a related question:

Companies have to quote averages because of the natural variations in wood from lot to lot. It probably is not cost effective to do physical property screening and blade construction reengineering based upon the properties of the wood as is it received from week to week. The same effects show up in multi-ply blades Wood has unique independent mechanical properties in the directions parallel to grain; radially normal to the grain rings; and tangential to the grain rings. These orthotropic physical properties are effected by, and are referenced during measurement against the moisture content % of the wood. I don't know if the time taken to achieve a target moisture content % effects material properties noticeably more so than the moisture content % itself or the original mechanical properties of the wood itself. I certainly however have heard of wood workers who prize wood that has been aged rather than kiln dried. In the multi-ply blades you are exploiting the freedom of using different grain directions and strengths to achieve the blade performance you want. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: garwor

Date Posted: 05/22/2013 at 8:25am

|

ah, this legendary topic from DTTW... ------------- http://stonitenis.rs/equipmentreviews" rel="nofollow - Equipment database Yinhe MC-2 FL fh: Xiom Vega pro bh: Xiom Vega pro Boycott Marcos Freitas for hidden services! |

Posted By: Tassie52

Date Posted: 05/22/2013 at 8:45am

|

This is my all time favourite TT thread! Do I understand more than a fraction of it? No way. Is it helpful? Yes indeed. Keep it coming, JRSDallas. |

Posted By: JRSDallas

Date Posted: 05/22/2013 at 11:34pm

|

Another question:

It appears to me that as the head size of a blade decrease the speed increases

to a point. I would think as the head got smaller the frequency would increase an hence the speed is faster. However this obviously cannot be a linear relationship as a blade that is just bigger than the ball would be very slow. Somehow blade weight and area must figure into the equation. I would think a graph of blade speed vs head size would be a sort of bell curve ? Do you think you could come up with an equation that relates blade speed to head size along with blade weight ? Original Answer:

As the head size decreases, the frequency increases fairly quickly since the term L in the denominator of the effective stiffness decreases.

However, if the blade speed at impact does not change, then the lower mass of the blade will act to lower ball rebound speed even as the blade becomes stiffer. This is due to the reduced forward momentum in the system during the collision as the bulk of this momentum is from the mass of the blade. However, as the blade gets lighter you also can swing it faster (up to a point) which offsets the decrease in the mass contribution to the momentum. When among of all these offsetting effects one will come to dominate can be calculated but it still will include assumptions that have to be controlled for. For instance, as you make the blade shorter, you also make lever arm of where the ball hits on the face of a small blade shorter versus where the ball hits on the face of a longer blade. I would assume that the ball hits a bit further out on the bigger blade (on average) and due to the rotation of the player's swing, the blade tip should be moving faster than the handle, and so the point of impact being further out will have higher blade speed during impact. As a player, your body is already instrumented with a sensitive set of sensors that can detect the differences in rebound velocity and efficiency and this is what we are all talking about when we talk about 'feel'. Now I've thought about calculating the effect of these issues and the effect of blade shape on mode frequency but I spent a good deal of time since the posts learning and doing finite element analysis of the single and multi-ply blades. Unfortunately, my student intro software license doesn't let me solve complex multi-body problems (the software can solve very complex structures but you have to buy the big bucks license to use it on larger problems). I found that I was spending more time trying to construct the problem to fit within the limits of the license than simply being able to solve the problem. Even so, as a result of my limited investigations on blade mode frequencies vs material selections I began to get interested in how much a person's grip effected the mode frequencies of the blade. (Note - In baseball and tennis and golf, it does not matter how tight or loose you grip the racket since the collision occurs in a time shorter than the round trip speed of sound (in the material) from the impact point to your hand and back. The vibrations of the bat, tennis racket or golf club do not effect the results of the collision. Table tennis on the other hand seems to have an interaction since the collision duration time is sufficient for the racket to deflect and rebound within the time frame of the collision (catapult or trampoline effect) and the distance to the hand is short enough for the interaction with the hand to have some effect as well. I am not able to model this even roughly yet due to the license limitation and I have not even added the rubber & sponge. I still want to get there though. Anyway, I stopped working on it for a while as I've been playing more and calculating less. If I get another head of steam worked up and make some progress I might get results, but right now its still a pretty complex problem. Further answer related to concept of intrinsic stiffness of a material:

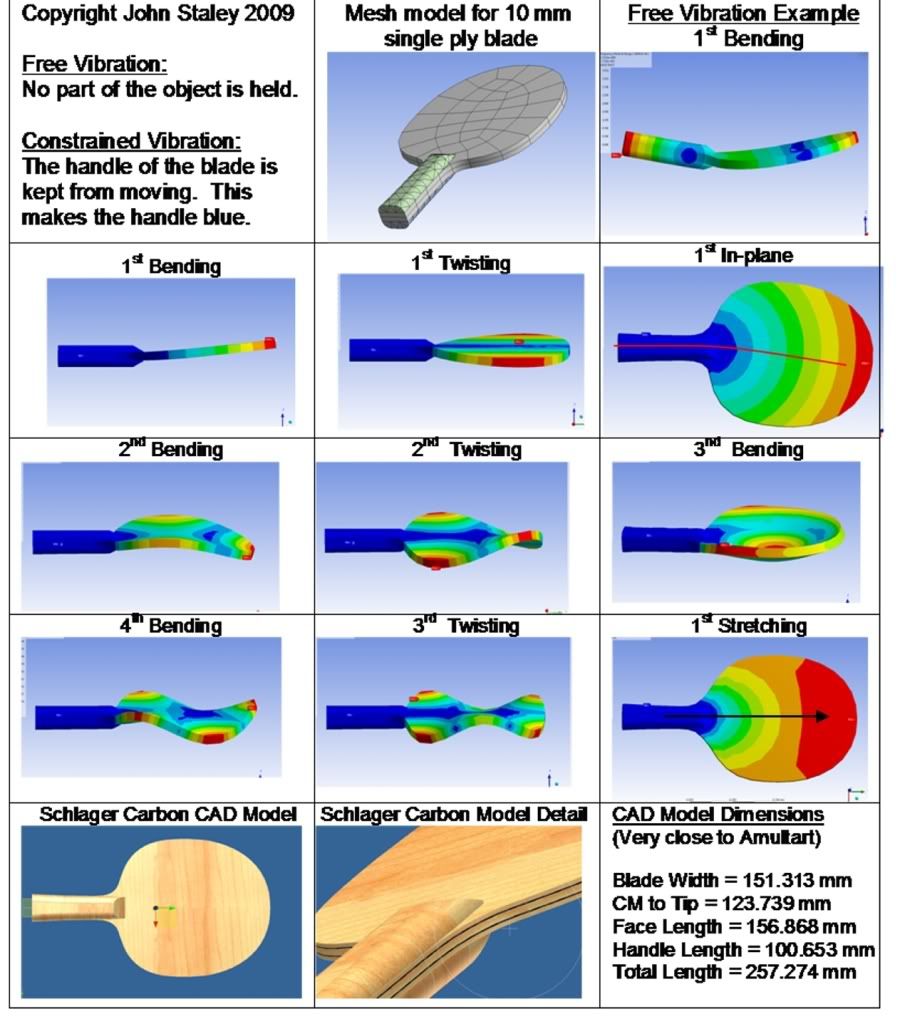

Many years after my initial thread I learned of how the intrinsic stiffness of a material effects the frequency of the vibrational patterns of a shape. Now we have seen side views of some of the calculated vibrations of a flat strip when I presented Beam Theory. When you perform these calculations in 3D on any shape using a finite element modeler such as ANSYS or CREO, you can see the shape and its natural vibrational modes (the exact same vibrations that a guitar string shows or a violin body shows). Everything vibrates with its own scale of multiple 'notes' where the frequency of each note is a function of stiffness and shape. These standing wave vibrational patterns each have their own frequency. (Physicists call such standing wave solutions Eigen modes of the system).

Now - The blade frequency vs stiffness equation presented in beam theory includes an insight between the material used in the shape and its frequency of vibration for given shape and vibration pattern. In short if two materials share the same ratio of modulus of elasticity (E) to density (r) then when they are made into exactly the same shape, then the same vibration patterns (identical shapes made from different materials have identical vibration patterns but different frequencies of vibration) have the same frequencies. Also the frequency of vibration of a shape that you hear with your ear is proportional to the square root of E/r, and is defined as the intrinsic stiffness of the material. So...If you can design a blade with the same intrinsic stiffness as a heavier blade, it will feel the same on ball impact and have the same speed of rebound as the heavier blade. NOTE: You will also probably swing the lighter blade a bit faster for the same energy input and thus actually end up with a bit faster rebound. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 05/22/2013 at 11:47pm

|

I've done a good bit of work since the earlier posts and I've made a number of measurements of bare blade frequencies and frequencies when rubber is added. So far I have an interesting collection of observations and models but no truths to state so I won't try to state any in this post. In my earlier posts I used proper terminology but people might not be familiar with it. "modulus of elasticity" is a measurable and well defined engineering property of materials and it is somewhat akin to a spring constant within the material, i.e. how strongly the material responds to elastic deformation. Flex is the geometry dependent extrinsic inverse of the modulus of elasticity as a higher modulus material would have a lower tendency to flex under a given load. As I explained early in the posts, non-linearities such as viscoelastic behavior and plastic deformations can be delt with by more complex (tensor) descriptions of the modulus of elasticity, but in TT blades, we are not seeing our blades stretch out of shape or take a permanent bend in them or become stretchy like a rubber sheet. Flex and its actual inverse Stiffness, are both extrinsic properties of an object, and thus they are an outcome of both the specific shape and thickness of the blade and the materials used to construct the blade. Modulus of elasticity is strictly an intrinsic property of each material used within the structure and it doesn't matter what thickness or shape you use of that material, it will have the same modulus of elasticity. Density and resistivity are additional examples of intrinsic properties of a material. The density of lead is the same regardless of if you have only a small fishing weight or a nuclear reactor lead radiation sheild worth of the material on hand. The total weight of the amount of lead you have on hand however is an extrinsic property, and so you expect that the fishing weight and the nuclear radiation shield might have different weights since they have different amounts of lead. Now the blade design equation does decribe the behavior of the rectangular cantelever constructed as a symmetic laminar beam. You can see from the calculations what each layer contributed to the overall stiffness and frequency of vibration. However, you can also see from the formula and the calculations that the contribution of a layer also depends on how thick it is and how far away from the center of the layer stack it is, and how heavy that layer is. All of these effects contribute to the stiffness and density and mode frequency values of the composite beam. One could easily compare the effect of using balsa between the rosewood plys versus the basswood with rosewood blade that I calculated. I would fully expect that the balsa wood would cause the mode 1 frequency to rise because it is lighter and so the overall mass of the beam would decrease (which increases frequency) although this would be countered by the lower modulus of balsa versus basswood. However, since the balsa/basswood switch is occuring in the center ply, the second moment of inertia contribution of the change in modulus is not as amplified as it would be when switching an outer ply between two different materials. Now once you have calculated the frequency of the multi-layer structure, you can use the resulting frequency and total mass and total thickness to go backwards through the formula for a single ply and calculate an "overall modulus" for an equivalent but fictional "overall" material of the single ply. The resulting engineering properties calculated material would likley lie outside the range of engineering properties of knowns woods if the original lamina beam contained synthetic materials (such as carbon) that were used in such a way as to take proper advantage of the synthetic material. Quite often laminar beams take advantage of synthetic materials simply to improve material property uniformity within the beam and not to create a beam material that has "non-wood" performance. The goal is more to have a beam that is made of a more "perfect wood" without the defects that exist in all but the best old growth and highest grade of a given wood. A similar example of the former case would be to back calculate through a similar beam frequency formula describing a carbon graphite tennis racket and trying to find an "overall wood' that would deliver the same properties. You can do the calculation, but you can't actually purchase any of the resulting calculated wood because it doesn't exist. Wood just doesn't have the same material properties as carbon-graphite. It is too bad that pictures cannot be easily posted. I've got some cool ones. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 05/22/2013 at 11:51pm

|

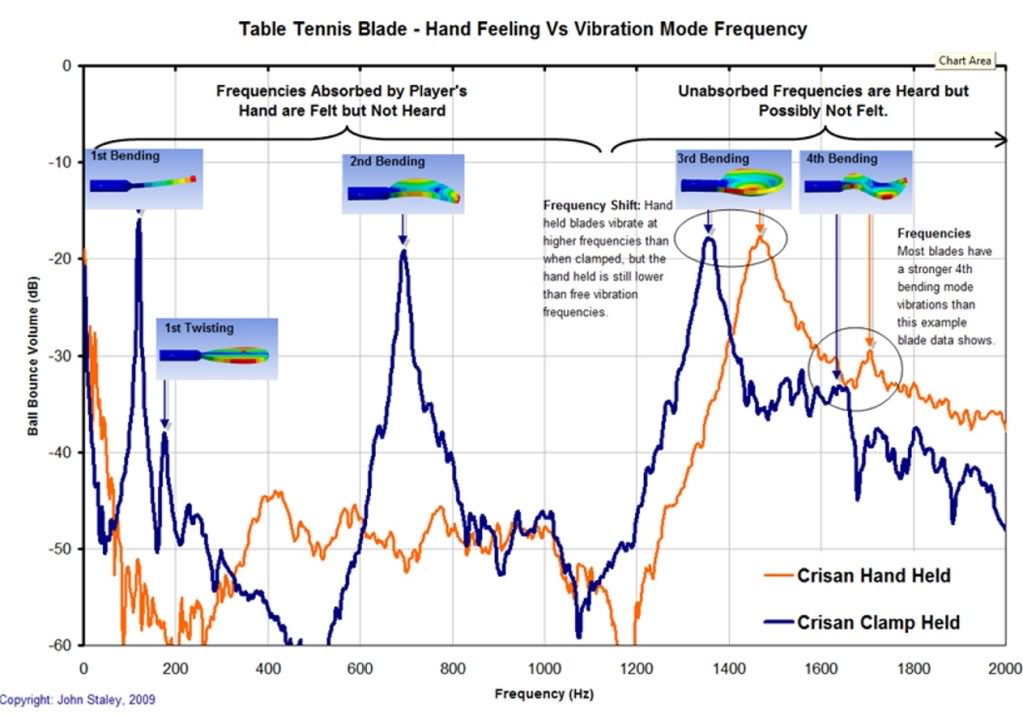

OK, I now have figured out how to include pictures into a post. Here are pictures of the shapes of the first 9 vibration modes of a shakehand blade (Amultart dimensions).

http://i640.photobucket.com/albums/uu127/JRSDallas/TTBladeModes.jpg">

In addition, here is a picture of the vibration spectrum of a bare shakehand blade under two conditions: 1. Handle is held by hand (quasi constrained vibration). 2. Handle is held by clamp (constrained vibration). http://i640.photobucket.com/albums/uu127/JRSDallas/HandDampingofBladeFrequencies.jpg">

JRSDallas2009-06-14 00:22:38 ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 05/22/2013 at 11:52pm

|

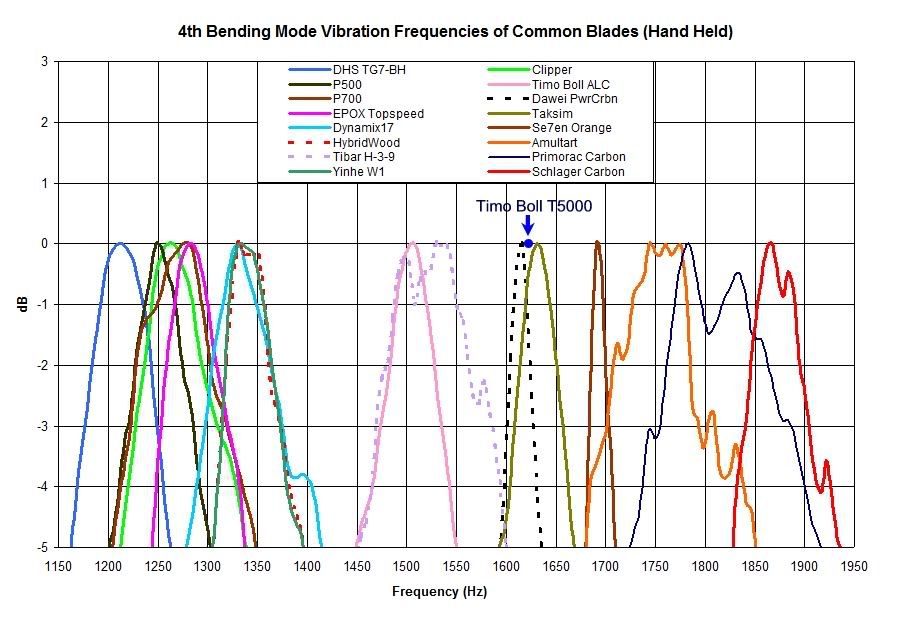

Here is a chart of the 4th bending mode frequency peaks of common blades. This data was taken by holding each blade by the handle only and bouncing a ball on it. You don't feel the 4th bending mode when you play but you do hear it when you bounce the ball. The 1st, 2nd and 3rd bending modes are absorbed by your hand and so you don't hear them (you feel them). In any case, the higher the frequency the faster the blade. You can tell from the graph that as you move to higher frequencies, there are no all wood blades, only carbon or other composites. This is because you can't make an all wood blade as stiff for a given weight (and thus fast) as a composite blade can be made. http://i640.photobucket.com/albums/uu127/JRSDallas/VibrationFrequenciesofCommonBlades.jpg">  ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: tt4me

Date Posted: 05/23/2013 at 12:33am

|

I am not familiar with all those blades. Are any of them made with a single ply of hinoki? I have never used a single ply hinoki blade but I have read that they are very fast, as fast as carbon blades or faster. ------------- Samsonov Alpha+H3 Neo+802 1.5mm, the Ball Whacker is revived!<br />Samsonov Alpha+H3 Neo+802-40 1.8mm my back up<br />BCX5+H3+802-1 1.8mm New but promising.<br /> |

Posted By: JRSDallas

Date Posted: 05/23/2013 at 6:00am

|

You don't have to be familiar with all of them but you may be familiar with some such as:

Hinoki Single Ply (Speed of single ply's is calculated in part IV)

Stiga Clipper (Clipper) - Frequency measured

Butterfly Schlager Carbon - Frequency measured and calculated

Butterfly Timo Boll ALC - Frequency measured

The point of the thread however is that you can predict the speed/feel of a blade based on knowing its layer thicknesses and materials. Stiffer blades have high frequencies and are faster. Not discussed in this thread are the secondary effects of the material selections such as Janka hardness (hard top surfaces give a hard bounce feel but will not cause the overall blade to be faster than its overall frequency), and damping (aralyte-carbon or Kevlar carbon have higher damping than carbon alone but less stiffness). So, if you want the dampled feel of an Aralyte-Carbon with the speed of a Schlager Carbon, then the center ply will need to be thicker than the 4mm center ply of the Schlager in order to help offset the reduced stiffness. The Dawai Wavestone is an Aralyte-Carbon with a 5.5mm center ply and as a result is MUCH faster than a Timo Boll ALC. While fast, it is not as fast as a Schlager Carbon however since the thickness of its Aralyte-Carbon layers is less than the Schlager (main reason) and since its head size is larger. On the other hand, the DONIC EPOX TOPSPEED is an all wood blade with maybe 7mm thickness (Schlager is 7.4mm but with carbon plies surrounding its 4mm thick center ply) and advertised as "TOPSPEED". The truth however is that the speed of this blade is at best middle of the pack, and the Clipper is even slower.

Single Ply Example: A 10 mm single ply hinoki (or balsa or any uniform material blade) is much faster than an 8mm single ply of the same material.

Relative stiffness of 10mm single ply vs 8mm is (103 / 83) = (1000/512) = 1.95, i.e. 95% higher.

Relative Frequency of 10mm single ply vs 8mm is = (103 / 83)1/2 = (1000/512) 1/2 = (1.9531) 1/2 = 1.40, i.e. 40% higher than 8mm. The higher frequency is what you hear with your ear and feel when you play. If you want a single ply hinoki that is as fast as a Schlager Carbon, it needs to be 10mm thick which feels pretty thick if you play shakehand. You could make your single ply 12mm thick and get an even faster blade but the resulting blade may be too thick to feel good in your hand (especially if shakehand). ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: Zhaoyang

Date Posted: 08/09/2014 at 10:13am

|

JRSDallas, thank you for the heroic effort! This post is about damping. (Aside from the whole blade moving in the power-absorptive flesh of the hand), it looks like first bending is the dominant contributor to damping. I think this because it takes a lot more power (don't remember the math) to produce lower frequency sounds of the same volume, and your bottom graph at (Posted: 22/05/2013 at 11:51pm) shows 1st, 2nd and 3rd bending at about the same amplitude. I'll think of the first as dominant, with some power lost in the wood and the rest dumped into the hand. So the clear and low "tok" in my MPM that I hear but don't feel, and suspect is the 3rd, is just an audible indicator that the blade *also* has a lot of 1st. But I suspect that if the ball stays on the rubber long enough (long enough for the whole blade to move in the flesh of the hand), then the effect of a varying grip dwarfs all of the above.

|

Posted By: lineup32

Date Posted: 08/09/2014 at 12:37pm

The ITTF allows up to 7.5% of a blade to be non wood material such as carbon, wonder what the impact would be on blade speed if the percentage was doubled for instance and if so what it actually make a difference in the lift of the ball?

|

Posted By: SolidEvolution

Date Posted: 08/10/2014 at 12:16pm

|

Alright, so if that's the deformation of a bat with a supersonic ball. Clearly the threshold for measuring the material is set to low. What they should have done was shoot a whole bunch of balls against a whole bunch of blades and actually be able to see how all that vibration affects the blade. And then still, if you factor in rubbers, whatever values that resulted in go's out the window. Cause if there is 1 thing that messes up measured vibration, it's rubbers and sponges. Throw in grip strength, and the variation is un-measurable. If this is really about damping, or lack thereof resulting in speed. Well, fast blades are not the best blades. As for: I suggest "bribing" Ross Leidy into writing a lengthy article. |

Posted By: AgentHEX

Date Posted: 12/02/2014 at 6:59pm

|

For the record here, a key assumption in the blade speed proxy calc above is wrong, thereby greatly reducing the predictive power of beam freq. The rate of rebound is not synonymous with first bending freq. Rather the inherent rebound freq of the ball is much higher at >1khz, shown in brief here: http://mytabletennis.net/forum/forum_posts.asp?TID=69265&PID=841869&title=will-it-burn-various-tt-ball-halves-ignited#841869 We can demonstrate this with further evidence of dwell times incl video or simulation (eg http://cofrest.info/md3.htm) etc, but there's also a simpler conceptual explanation. Freq and various other similar measures like stiffness are unbounded metrics, while "speed" is a direct function of coefficient of restitution and thereby similarly bounded to <1. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: JRSDallas

Date Posted: 12/03/2014 at 11:54pm

Of course its impressive seeing what a supersonic ping pong ball can do. At the same time it is hard to see high order bending modes in a video since the visible amplitudes of vibration modes of the blade (or violin, or vibrating plate) are pretty small. You will need a more sensitive way of videoing deformations before you will clearly see higher order bending modes. Of course with an impact energy high enough to break the racket, the first bending mode is really visible (and changing as the face detaches from the handle). If you want to see bending modes made visible, look for video's of vibrating plates where a thin layer of sand has been placed on the plate, you will be able to see the various bending modes create increasingly complex patterns in the sand. The table tennis blade is the same as the plate except its shape and construction causes its bending mode sand patterns. If you are a mechanical engineer, the vibrational (or resonant or eigenmode) modes of structures is a familiar topic.

Yes, but the calculations do show the effects of blade construction. The mass of added rubbers shifts the combined system's bending mode frequencies lower, but the overall system still retains its various bending modes. Further, since the frequency shift is due to added mass alone, a low frequency blade will still be at a lower system frequency than a high frequency blade will be once both have the same rubbers attached. Of course the rubber mass alters how the blade feels when you swing, and the rubber's dynamic behavior alters the feel, energy losses and dampening of the overall system when in a compressive (smash) or extensive (brush loop) or mixed (loop drive) collision with a ball. Analytically solving for an optimum solution of a combination of layers of woods, synthetics, adhesive, pip interface and rubber top sheet, much less with the further interaction of grip strength, swing mechanics and energy transfer between the body to arm to blade to ball is way beyond the ability of anyone on this forum. Still, the question of the original thread was about the playing characteristics of wood and my intent in investigating an answer was to show how wood properties, layer thickness and synthetic material layers interacted to achieve an overall effective behavior of the blade and one's playing perception of blade speed. My stab at the restricted problem of idealized blade construction while not a full solution does provide a lot predictive insight into how a blade's design will effect its playing feel. NOTE: My original thread did discuss that there was a lot that still needed to be done to get a fuller picture but that portion of the discussion and various Q&A posts is not re-pasted into this thread.

And fast cars are not the best cars, (unless you like and can drive fast cars well), but for the most part regardless of our car driving skills, we can tell difference between a fast car and a slow car when we drive it. The same is true with table tennis blades. You can tell a fast blade from a slow blade when you play with one even when both blades have the same rubbers. You also will find that the faster blades have higher frequency. Note: A good test of blade frequency is to use your finger tips to grab the face edge at two points about 2/3 the distance to the tip of the blade. Now gently holding it there, lightly bounce the handle on the back side of your skull. You will hear the pitch of the blade (without the hand damping out the first bending mode). You can to the same thing with rubbers attached and then hear the lower pitch of the full blade + rubber system. Faster blades will be higher pitched, but if you put a dead rubber on that blade, you can still kill the rebound speed of the system. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 12/04/2014 at 1:23am

Very true, Coefficient of Restitution (COR) is a direct measure of ball rebound speed, and it is bounded, but, it does not tell you anything about how to design a blade with high COR. However, analysis (not presented in detail here) does show that frequency is a generally good predictor of COR. Specifically, complex mass spring system collision modeling shows in general that stiffer, more rigid (higher mode frequency) objects have higher COR collisions while more flexible (lower mode frequency) objects have lower COR collisions. (SIDE NOTE: The COR of a blade also varies across the face of the blade with its maximum value occurring at the center of percussion. Explaining the reasons for this variation is another topic but it is also tied to coupling of collision energy into the vibration modes of the blade.) Every material (wood, carbon, rubber...) has a modulus of elasticity and a density and it is these mechanical aspects of these materials and their organization into layers that drives the final mechanical stiffness of the blade. I use blade frequency as an predictive measure for blade speed since (1) it is tied to system stiffness, i.e. to the (square root of the) ratio of elastic modulus divided by the density, and (2) since frequency is easily measured by your ears when bouncing a ball on the blade or when bouncing the blade on your head. Finally, my real world test results of frequency data for the blades I measured and have played with*** very strongly correlates with known fast blades (Schlager Carbon, Amultart, Primorac Carbon) having higher frequencies and known slower blades having lower frequency. ***Your Mileage May Vary: My playing style is power oriented and I like the directional feel of the ball colliding with the blade while loop driving with hard sponge max rubbers. A player with a spin oriented brush contact game may be striking the ball in a way that drives more of the collision energy tangentially into the topsheet and sponge than into compression with the blade. Such a player could have a much different perception of what blade is faster for them than I might perceive for myself. In such cases, we might also want to start measuring a tangential collision COR arising from tangential impact with the blade + rubber system. That ain't easy to measure, and it absolutely ain't easy to calculate but if someone works it out, share the wealth. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: AgentHEX

Date Posted: 12/04/2014 at 3:04am

|

I do agree that freq will correlate with COR better than, say, stiffness. But it seems that's much due to the happenstance of the basic math relationship, namely stiffness as ~x^3 polynomial creates run-away divergence vs properties like thickness, whereas freq vs same has more linear results. The latter will appear more similar to asymptotically bound than the former, but so does any straight line. Frankly I think a basic (math) transform of almost any sane metric into something that converges to a constant (in this case the COR of the ball) will be similar enough that only careful empirical testing can discern which is better if any. Regardless, the greater point is that one of the core misconceptions in TT from which many others stem is the blade/racket somehow propels the ball (via bending, "catapult", etc), when really it's the ball propelling itself before heavier actors do their thing; and slower equipment is just by definition greater loss/inefficiency against that. === >A player with a spin oriented brush contact game may be striking the ball in a way that drives more of the collision energy tangentially into the topsheet and sponge than into compression with the blade. Such a player could have a much different perception of what blade is faster for them than I might perceive for myself. Yes, my own experience is that slower blades allow a faster swing which is esp useful against backspin. TT at club levels tends to be limited more by control than physical or equipment speed potential. The common explanation for the slower-blade/more-speed phenomenon is that the blade "flex" swings back to "catapult" the ball which can't be the case as mentioned. I created this thread here which starts off trying to explain where this myth might originate but ended up covering a lot of this ground. Consider perusing at your disposal and I'd be interested if you find anything wrong: http://ooakforum.com/viewtopic.php?f=43&t=26662 ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: JRSDallas

Date Posted: 12/04/2014 at 9:34am

Just to clarify for readers: 1. It does not matter that a descriptor of physical behavior is unbound. Whole numbers are not bound, and they can be used to count to a (countable) infinity. Being unbound has nothing to do with how useful they are at counting. 2. The original thread describes the math physics of a symmetrically constructed laminar beam as an approximation to a TT blade construction. The math shows that the sound of a blade is intimately tied to the physics of its construction. If the structure is a simple shape, you can use its sound, weight and dimensions to directly measure the structure's mean elastic modulus and mean density of the material. Companies do use this technique to measure. I use it to tell me how fast a blade is.

Agree. The blade generally does not propel the ball via bending and recovery, i.e. "catapult". Normally there are only energy losses arising from blade bending (energy losses reduce COR) because the ball is gone before the blade bends or bends back. Making the blade stiffer reduces the energy losses in the collision (i.e. keeps COR high). However, there can be contributions to COR from some blade bending modes and from recovery of the sponge from its impact with the ball if they can act to return energy to the ball within the time frame of the collision with a ball. Some blade, rubber and ball collision combinations satisfy this during certain strokes. Collisions of a TT ball with typical inverted rubber blades actually last about 3-4 msec i.e. (circa 250 - 333 Hz) so physical resonances that can positively respond in that time can contribute to COR. "Catapult" effects can occur when the system contains components that can respond in phase during the time frame of the collision. Ball collisions with slow soft blades may not compress the ball (natural frequency of 40mm celluloid is about 5 kHz), and in this case the bulk of the energy storage and return to the ball occurs in the rubber and blade. "Catapult" is a real phenomena, but it really only means that you found a system resonance where the energy losses are reduced so that the slow blade feels less slow in that circumstance and its COR in that circumstance is closer to 1. ===

HEX, Your bringing up the issue of catapult in this thread makes a good point. I personally don't like catapult in my racket since it makes me uncertain about where the ball will go. I'll read your thread! Have a good one. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: cole_ely

Date Posted: 12/04/2014 at 10:56am

|

Holy cow! This takes EJ to a whole new level. Now people are going to be emailing me wanting to know the specific gravity of each ply of every one of my blades! ------------- Wavestone St with Illumina 1.9r, defender1.7b Please let me know if I can be of assistance. |

Posted By: AgentHEX

Date Posted: 12/04/2014 at 1:04pm

I believe this is our point of contention. Every piece of evidence I've seen related to dwell implies it's <1ms: 1. Empirical high speed video of collision. One of which is linked from the thread above: https://www.youtube.com/watch?v=vP_hNJcGDmY (shift-J/L to advance by frame), and another from a member here. Both at 1000fps show the ball on the racket for <1 frame. 2. Rudimentary calc assuming sprung system with certain travel and impact speed. One of these is linked above assuming ball is the string and weight using ITTF hardness spec for travel (~0.7mm @ 50N). This is also possible with even less assumptions by simply noting that given a well hit shot of 10-20m/s and only 2mm of travel in the rubber at best the timeline involved just can't be very much. -- Also another thing worth noting related to freq as metric is that it probably doesn't apply across different blade sizes. Otherwise an extra tiny or massive novelty blade of same construction would vary substantially in speed/COR which doesn't seem right without even testing. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: Peergee

Date Posted: 12/04/2014 at 1:24pm

|

@Cole Your teaching career should come in handy..... haha ------------- My Feedback:http://mytabletennis.net/forum/forum_posts.asp?TID=68326&PID=826612 TBS Tenergy 64 Juice Patisuma |

Posted By: JRSDallas

Date Posted: 12/04/2014 at 5:12pm

|

The dwell time I noted was from memory of a paper I have not seen in 6 years, so maybe my memory is wrong. Still the physics is the physics so lets drop the numbers and look at the forest it has made: 1. When collisions of a TT ball and TT paddle occur, physical resonances that return collision energy to the ball within the dwell time contributes to COR. 2. When comparing two otherwise identical blades, the blade with higher frequency is both the stiffer of the two, and it will generally exhibit higher COR. 3. You are obsessing on the term "metric". I suggest we make up a new word: QPONLI = "qualitatively predictive observable non-linear indicator". EXAMPLE: A good qponli when comparing two otherwise identical blades, is that the blade with higher frequency will generally exhibit higher COR. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: JRSDallas

Date Posted: 12/04/2014 at 5:24pm

Cole, You should know that all I have ever asked from you on blade purchases (Wavestones and a T-1) is to weigh the ones you have on hand and to bounce a ball on them so you I can hear them over the phone or so that you can pick for me the one with the highest pitch (frequency). JRSDallas ;-) ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: AgentHEX

Date Posted: 12/04/2014 at 7:30pm

|

> 1. When collisions of a TT ball and TT paddle occur, physical resonances

that return collision energy to the ball within the dwell time contributes to COR. I believe the spring of just the ball itself is adequate to explain this. After all it bounces quite well on a infinitely thick/stiff surface. The blade/rubber/table/etc can and will take away from that, but not adding to it in the timeframe of the impact. Another source of dwell I forgot to put in the list above is physics simulation a la: http://cofrest.info/md3.htm; it also estimates <1ms. To flesh this out a bit, it seems ball/blade/rubber all work in their own freq bands far as resonant "catapult" goes. The analogy I use in that flex thread is pumping up/down real fast on a trampoline does appear to move things around, but not necessarily the expected effect. > 2. When comparing two otherwise identical blades, the blade with higher frequency is both the stiffer of the two, and it will generally exhibit higher COR. The thought experiment to try is that two blades (or tables, etc) with greatly differing sizes will have differing freq but near same stiffness. I suspect the bounce correlates better to the latter QPONLI. IOW, freq works alright since our blades are more or less the same size. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: Baal

Date Posted: 12/04/2014 at 11:30pm

Thank you for this one. Nice and straightforward. |

Posted By: JRSDallas

Date Posted: 12/04/2014 at 11:35pm

1. Derive the physics of ball to paddle collision as I have done with blade construction. The insight is the equation. 2. Regarding my thread and derived equation, I think you have been relying on words to define your understanding rather than understanding the equation itself (pasted again below). It explicitly describes the relationships between mode n, angular frequency w, frequency v, elastic modulus E, moment of inertia I, length L, and area A for the blade approximation explored in the thread. It exactly shows how frequency v changes when you change ANY other parameter. No thought experiment is needed, just read it. It is my words. Further you can also use it to solve for alternative layer constructions that yield the same frequency - i.e. an infinity of different ways to build blades that feel the same. Finally, since most people are choosing between blades of similar size, they can use the insight from the equation to understand which ones will be in fact be stiffer or more flexible based on what little data is provided by manufacturers and pictures of blade layers. They won't be left believing someone's post saying how some blade behaves versus another when they can see from its construction that it can't and learn from the subsequent hole in their wallet, that it doesn't. The general frequency vs stiffness equation for symmetrically laminate multilayer construction blades is:

The mode n=1 equation is:  ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: igorponger

Date Posted: 12/04/2014 at 11:42pm

|

ЦИФРЫ ПРАВДУ ГОВОРЯТ. Зачем мне ваши обширные обзоры цветастые, многословные? это фокусы придуманы для девочек охмурять. Девочки любят ушами. Для мальчиков и мужиков нужна простая и ясная оценка продукта, несколько скупых цифер, десятибальная шкала. КАК ДЕЛАТЬ ОЦЕНКУ. Берем эталонную резину типа тенержи. Все игровые характеристики 10 баллов. И делаем оценку продукта сравнительно к эталону. Человек кто умеет оценивать продукт в баллах это настоящий эксперт достойный уважения. Краснобай многоречивый это не эксперт ни разу.. У немцев лучший оценщик работает на фирме CONTRA в Гамбурге. Это подлинный талант. Каталог КОНТРА самый лучший каталог теннисной продукции.. ТРЕБУЕТСЯ ОПЫТНЫЙ ОЦЕНЩИК Буду по гроб жизни благодарный если кто сделает сравнительную таблицу для китайской резины, по всему списку Еченг. Это надо будет лично посетить Китай и работать там на складе еченга. тестировать резину за теннисным столом. Кто смелый? http://www.contra.de/katalog/Contra_Katalog_2014/#64/z" rel="nofollow - http://www.contra.de/katalog/Contra_Katalog_2014/#64/z |

Posted By: JRSDallas

Date Posted: 12/05/2014 at 12:26am

|

------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: AgentHEX

Date Posted: 12/05/2014 at 1:01am

|

> Derive the physics of ball to paddle collision as I have done with blade construction. The insight is the equation. This is not only non-trivial but if you look at the hollow sphere sim, it's questionable whether it's even possible. However a simple string model isn't going to be off by much and is consistent with basic material stress/strain principles, and certainly not by the near order of magnitude discrepancies in the ball/blade frequencies. I mean, calculating the basic mechanical displacement of certain ball impact speed (~10m/s) over a certain distance (~mm) isn't a trick, it's a basic sanity check. In this case, unless the racket somehow holds onto the ball for many ms (a violation of physical continuity), there's no way it overlaps the bending frequency/period of the blade. > It exactly shows how frequency v changes when you change ANY other parameter. I can see the equation and I don't doubt that the frequency changes with respect to size or any number of params, but my point is whether frequency as indicator has predictive power over varying blade size. We can do the tiny vs massive blade (or table) test, but I think we both know the likely result. There might be some effect at the extremes (esp small mass), but at all sane sizes it's all going to be ~same. As another sanity test, the "sound cone"* of the impact is ~2m at best over evident dwell length (and half that for an interaction to come back), and that equation certainly scales beyond this. *conceptual equivalent of relativistic light cone. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: AgentHEX

Date Posted: 12/05/2014 at 1:10am

|

Also a brief note to igor and those similarly skeptical of what science can do: consider the amount of human progress in the last few hundred years with science, vs all of human history prior when people relied on their gut. I don't think there's much doubt where they'd prefer to live. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: AgentHEX

Date Posted: 12/05/2014 at 2:48am

|

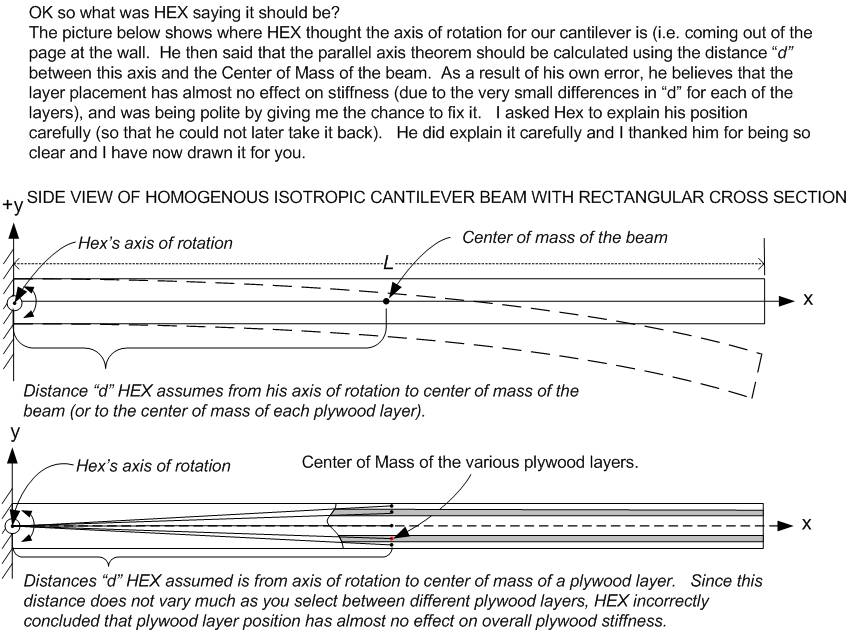

BTW, I looked at the equation a bit closer and don't understand how

the

Parallel Axis Theorum is being applied. The "d" is

supposed to be magnitude of displacement to the center of rotation

(which is why

it's squared), but surely the ply layers don't rotate with respect to

the centerline. I can see you're trying to bring in a

corrective factor, but this doesn't look to be it (basically you're

offsetting the outer layers in the wrong direction, towards the blade tip). Fortunately this effect is mitigated by relatively small size of d. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: lineup32

Date Posted: 12/05/2014 at 12:34pm

| thanks for this thread, very interesting points of view and meaningful for players if they pay attention and follow. The link to : http://cofrest.info/md3.htm; thanks! very informative |

Posted By: Baal

Date Posted: 12/05/2014 at 12:56pm

|

Igor is the guy who once repeatedly demanded numbers on another topic ("because I am construction engineer"); criticized all of China for not knowing science; and now that he is actually been given something quantitative (in a more abstract form) finds them not manly or plain enough. Oh well. |

Posted By: JRSDallas

Date Posted: 12/06/2014 at 10:47am

|

HEX said "......there's no way it overlaps the bending frequency/period of the blade." Already fully discussed but also irrelevant to issue of how to design a blade. You are missing the big picture. I don't care about rebound time, I care about energy losses arising from collision. Energy is lost to the blade when you couple collision energy into the blade's vibration modes and this always reduces COR. There is the discussed resonant case of energy return from a single vibration mode but the remaining spectrum of blade's vibration modes won't simultaneously be resonant, they will just be radiating absorbed collision energy as sound. Less energy is coupled into stiffer blades and so they have generally higher COR. Someone may not like fast blades. OK they can use the information to pick a slow one before spending their money. Hex said "..but my point is whether frequency as indicator has predictive power over varying blade size." Most blades fall into a fairly small size range so from a practical standpoint, YES the frequency of a blade is a good predictor. My empirical data for over 30 blades also supports this. If you personally are choosing between two identically constructed laminations but one blade face is the size of your palm and the other is the size of a dinner plate well then you have two choices: (1) Try them. (2) Calculate the expected frequency shift due to the dimensional differences. Otherwise stop worrying about if frequency is predictive of COR. It is (in general). Hex said "I looked at the equation a bit closer and don't understand how the Parallel Axis Theorum is being applied." The distances "d" are perpendicular to the plywood face of the blade and are measured from the center of the plywood stack to the center of the layer in question. The equation is not a correction factor, its just the math. Lookup moment of inertia, it explains why steel I-Beams and engineered wood I-joists look the way they do. Hex said "Fortunately this effect is mitigated by relatively small size of d." Understanding "d" (the placement of a layer within a plywood) is hugely important to how that layer contributes to the overall stiffness and blade speed. Moving a particular layer from the center outwards, rapidly increases the contribution to blade stiffness by that layer. Balsa and kiri are used as thick center plies because they are light and they provide a surface to glue on stiffer layer (such as rosewood, carbon, etc onto) that makes the plywood of the blade much faster without getting it too thick. Designers often then glue a somewhat softer wood on top of the carbon or ebony layer so as to give the blade a softer impact feel while not actually slow down the blade much. Designers that place stiff layers like carbon or ebony at the center of a plywood are making the least use of the strength of that material. Most blades don't use stiff layer at the center because its stupid engineering. Of course there is no shortage of people you can sell pyramid power to so it may be just smart marketing. Lineup32 provided the web link: http://cofrest.info/md3.htm; Thanks Lineup. Yes I know that webpage and I looked at molecular modeling when I was thinking about solving issue of rebound after collision. I think the best modeling path is to use a finite element analysis software that includes the ability to model elastic and inelastic collisions. I can't afford a probably $10K license and there are no "student" copies of such software tools that I know of. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: BH-Man

Date Posted: 12/07/2014 at 1:28am

|

JRS !!! ------------- Korea Foreign Table Tennis Club Search for us on Facebook: koreaforeignttc |

Posted By: Tassie52

Date Posted: 12/07/2014 at 5:22am

|

1

If blade frequency can be

used to predict blade speed because of its relationship to system stiffness,

then does it follow that calculating stiffness will also give us a measure of

blade speed? 2

The formula quoted above

uses “density”. Are you using

average dried weight (measured in kg/m3) rather than specific

gravity? 3 How is the formula applied? (I said I had trouble with numbers!) For example, if I know that PO cedar has an average dried weight of 430 kg/m3 and MoE of 11.35 GPa, then stiffness = √(430/11.35) ? Again,

I’m sorry if I have no idea what I’m talking about, but I would be really

interested to know if this produces some meaningful way of comparing different

timbers. Thanks. |

Posted By: JRSDallas

Date Posted: 12/07/2014 at 10:57am

|

My answers are in RED. Tassie52 asked: 1 If blade frequency can be used to predict blade speed because of its relationship to system stiffness, then does it follow that calculating stiffness will also give us a measure of blade speed? Yes system stiffness is a measure, but calculating it or measuring it is more difficult than listening to the sound the blade makes. Just trying to be practical. In the end, while I have calculated and made actual measurements, I only did it for the learning. It is faster and easier to just pick blade speed by hearing the tone. (If I can't hold it and hear the tone, then I fall back on looking at the plywood construction and knowing what makes it stiffer). 2

The formula quoted above

uses “density”. Are you using

average dried weight (measured in kg/m3) rather than specific

gravity? I use any weight reference I can find (dried, specific gravity, etc) and convert to the units needed. I don't use green weight as we don't use green wood in our blades. 3

How is the formula

applied? (I said I had trouble

with numbers!) For example, if I

know that PO cedar has an average dried weight of 430 kg/m3 and MoE

of 11.35 GPa, then stiffness = √(430/11.35) ? You can see the spreadsheet tables of calculations that I did for various rectangular approximations to blades earlier in the thread. However, I have only done these calculations for that original thread in late 2008. I did it at the time to illustrate that the formula results made sense, i.e. A 10mm single ply hinoki is fast - Yep the calculations predict that. An 8mm single ply hinoki is pretty slow - Yep the calculations predict that. The Schlager Carbon is pretty fast - Yep the calculations predict that. If you are designing a blade that you will build but want to optimize something, then go ahead and work out the calculations for some ply combinations you are considering. If you understand the equation though, you can see how the ply combinations effect the result and pick what you want to do. If your goal is to build a blade that is faster than Schlager Carbon, build a stiffer plywood. The lightest way to do that is to increase the thickness of the light center ply so that the carbon layers are moved further apart. Or, if you have a fabric with higher modulus than carbon, then use it instead of carbon and don't increase center ply thickness, or do both and get something much faster. If you don't like how carbon feels but still want a result that is still faster than Schlager Carbon then use Carbon-Aralyte and increase the center ply thickness even more to offset the lower elastic modulus of Carbon-Aralyte. The formula will help you determine exact thickness changes needed but you already know what to do. Now one can make accurate measures of blade frequency spectrum (handle in clamp, ball bounce at center of percussion, microphone, Fourier decomposition into frequency spectrum, identify spectral peaks - see pictures from the original thread). I also did that for 30 or so blades in late 2008/early 2009. I was not looking for the calculated frequency of my rectangle approximation to predict the measured frequency of a real blade with the same plywood, I was trying to see the behavior differences between blades matched what the calculations predicted. Yes, Schlager Carbon is far faster than Clipper. Yes, EPOX TOPSPEED isn't very fast even though the manufacturer (and CONTRA) rate it OFF+. Perhaps I got a bad one? No. The review is wrong. Can you hit a fast ball with Clipper and EPOX TOPSPEED, absolutely but you'll spend more energy doing it. So my recommendation is to understand the system behavior, not to calculate a particular output that results from particular inputs. I only bounce a blade (of normal size) on my head so that I can hear its tone (pitch, frequency). If the tone is higher than another blade, then it is faster than that other blade. If I am buying out of a catalog, then I look at its overall thickness and the layers in the plywood. Innerforce ZLC is absolutely slower than Amultart primarily because its ZLC layers are closer to the center and it is thus less stiff. ------------- Galaxy T1 89 gm FH: HRT Huaruite Wujilong 2 - Dragon 2 II, Max, Black Donic Acuda S2, Max, Red |

Posted By: AgentHEX

Date Posted: 12/07/2014 at 3:44pm

|

> You are missing the big picture. This is a good idea so I'll format the reply in order of stack ranked priority from broadest issue to most technical detail: 1. The key point to noting that ball/blade/rubber occupy different freq/periods is dispelling the erroneous mental image of TT ball interaction from which most others stem. If you look at nearly every equipment review/comment, even opening posts here, the basic idea is that ball rebound is directly coupled to blade and rubber characteristics (specifically the blade/rubber flexes back to repel the ball). This misconception has clear systemic consequences, not unlike the basic idea that everything revolves around the earth. If anything, removing that notion of coupling makes reasoning about the system easier. 2. My argument on frequency isn't that it's an invalid or even poor indicator/predictor, only that it has its own drawbacks. The first point was that conceptual correlation to ball rebound is not causal as mentioned in the posts. The second was it has coincidentally decent mathematical shape: from POV of practical "accuracy", all functions with ~this shape: http://www.wolframalpha.com/input/?i=-1%2F%28x%2B1%29+%2B+1 will predict relative COR across the range better than the indicators mentioned. They all happen to work OK for relative comparisons because slope ~= 1 in the blade thickness range, and how all contiguous functions are approximately linear for relatively small deltas. However mere numbers do not provide conceptual understanding, which is really what we're after here. This was why I mentioned that some of the necessary input params to freq can be misleading to such a goal. 3. On the d factor, consider a simple example: a rotation axis starts at center and moves to d=2, thus d^2=4. If it moves a further 2 units out in same direction d=4, d^2=16. However if it moves 2 unit perpendicular to first direction d= sqrt(2^2 + 2^2), d^2 =8. Ie. direction matters. The rotational axis in our case is initially "moved" to the end of the blade along the blade length. The "d" you're using is perpendicular to this direction. Also note the offset is not calculated relative to any axis, but to an axis through center of mass.* 4. >Understanding "d" (the placement of a layer within a plywood) is hugely important to how that layer contributes to the overall stiffness and blade speed. Yes, but not to frequency as noted (how would it from a physical sense perspective?). If you can imagine the particle sim of the blade the collision, particles closer to the surface surely matter a bit more than those deep. However this is a matter of degree, and the rigid coupling between those particles (ie solid) tends to make the object as whole homogenous. It's also likely non-trivial to model, esp with clean discrete equations from first principles. -=- edit: To flesh out this last point, recall that rotational inertia of an object about an axis cannot simply be reduced to operations its center of mass. Ie the edges of those outer plies certainly contribute quite a bit more than the middle which is d (a few mm) away, even if the plies somehow rotate around the center axis. To do the calc correctly we need to bust out geometric calculus. ------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: AgentHEX

Date Posted: 12/07/2014 at 3:50pm

|

Just to clarify on the I-beam point. The x^3 relationship is already encapsulated in the first term, this is about the "offset" second term.

------------- Science; upsetting the indignant since http://en.wikipedia.org/wiki/Galileo_affair#Inquisition_and_first_judgement.2C_1616" rel="nofollow - 1616 . |

Posted By: cole_ely

Date Posted: 12/07/2014 at 4:05pm

Makes sense that was you. ------------- Wavestone St with Illumina 1.9r, defender1.7b Please let me know if I can be of assistance. |

Posted By: Crowsfeather

Date Posted: 12/15/2014 at 6:53am

|

I will never understamd those math, but in short, thickness and composite type give a stiffness, in which effect how fast ball leaving your blade. And also stiffer blade tends to give higher pitch of frequency , im i right??? ------------- I'm no longer an EJ and I'm proud . |