|

|

|

MMaze vs Viscaria |

Post Reply

|

Page <1 2345> |

| Author | ||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 2:49am Posted: 08/14/2013 at 2:49am |

|

|

My 2 cents to the discussion as a material & wood specialist.

1. BTY M.Maze was designed with an outer ply in Limba. It's a fact that Limba is not as hard as Koto. A lot of players say the dwell time is longer and that it is more designed for looping. Let's assume it. 1 bis. TBS/Viscaria/ALC have Koto which is not considered by wood specialist as a hard wood (<> walnut, ebony, acacia...). 2. Excluding the outer ply the other wood plies are similar. Is there a slight difference in thickness ? Maybe... It can have an impact on the feeling only if this happens for outer ply (over the carbon fiber). 3. I would like to focus on the fact that when you say THE TBS is better/harder... than THE MM, it can not simply reflect the truth. Why ? Because wood is a living material (like you & me). You have "more" chances to have a difference between two MM or two TBS than between a given TBS and a MM. The wood of the same species differs in terms of hardness, density... depending of the country, the conditions of growth (weather, humidity, sun factor...), the conditions of transport etc... I guess that BTY is the manufacturer with the higher criteria of quality but it is simply impossible to guarantee the properties of a wood. So you'd better say: my TBS feels harder than the MM I tried. Do not hesitate to correct me. I gave this explanation in french on tennisdetable.fr but it is not so simple to write it in english. |

||

|

||

| Sponsored Links | ||

|

||

jonyer1980

Gold Member

Joined: 07/30/2008 Location: Spain Status: Offline Points: 1600 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 4:25am Posted: 08/14/2013 at 4:25am |

|

%100 agreed. Maze/viscaria/tbs/tb ac feel 80% similar each other |

||

|

Rosewood V FL

Nittaku Fastarc G1-FH Stiga DNA Pro-S MAX BH Avoid any Butterfly stuff... at abusive prices. Raw power without control means nothing |

||

|

||

SmackDAT

Platinum Member

Joined: 01/01/2012 Location: London Status: Offline Points: 2231 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 4:26am Posted: 08/14/2013 at 4:26am |

|

|

Yep.

|

||

|

||

kprimorac

Super Member

Joined: 12/18/2005 Location: Belgium Status: Offline Points: 277 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 4:38am Posted: 08/14/2013 at 4:38am |

|

|

I played with MM for more than 1 year, since this year, I switched to Viscaria, IMHO : · Control : overall, Viscaria has a better control than MM · Looping : depending your how you feel the ball, even Viscaria is harder but at high speed, it still has a soft feeling and very elastic · Speed : when you accelerate, Viscaria is faster with more power than MM |

||

|

||

J.P. Gatien

Super Member

Joined: 08/30/2012 Location: Germany Status: Offline Points: 182 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 4:41am Posted: 08/14/2013 at 4:41am |

|

Koto and Limba are almost the same in case of hardness. It's just the thickness of the outerply what makes the difference. Koto outerply's are usually a bit thinner then Limba outerply's that results in a crispy and hard feel in comparison to limba. Elastic-Modulus:(Koto) ~ 9200 N/mm^2 Elastic-Modulus:(Limba) ~ 9900 N/mm^2 Edited by J.P. Gatien - 08/14/2013 at 4:48am |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 5:28am Posted: 08/14/2013 at 5:28am |

|

|

Do not totally agree.

According to CIRAD: Koto (http://tropix.cirad.fr/Afr/KOTO.pdf) Density = 0,59 Hardness Monin = 2,5 Elasticity module = 13140 MPa (+/- 1400) Rupture flexion: 96MPa Limba/Fraké (http://tropix.cirad.fr/Afr/FRAKE.pdf) Densité : 0,54 Dureté Monnin* : 2,4 Elasticity module: 11750 (+/- 2480) Rupture flexion: 80MPa But the Limba/Fraké is well known for its high variability in quality (mechanical properties can differ by more than 25%). There is a note at the CIRAD about this. So, it's right that Limba & Koto are as hard but Koto is a little more solid and flexible (from 12% to 25%). That is the reason why I was talking about "feeling" and not technical/mecanical facts . You will note also that Elasticity module of Koto can be at 11740 MPa and Limba 14230 MPa but also Koto at 14540 MPa and Limba at 9270 MPa !! |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 5:39am Posted: 08/14/2013 at 5:39am |

|

|

I would like to draw your attention on the "facteur de qualité musicale" in the sheet, Q factor in english.

It's is a dimensionnless parameter that describes how under-damped an oscillator or resonator is or equivalently, characterizes a resonator's bandwidth relative to its center frequency. The Q factor of the Fraké is much higher than the Koto. Higher Q indicates a lower rate of energy loss relative to the stored energy of the resonator; the oscillations die out more slowly. |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 9:05am Posted: 08/14/2013 at 9:05am |

|

|

JPG has a pretty good point because overall stiffness varies quite nonlinearly with thickness so even minor change there can overcome diff between woods.

What I'm more interested in is just how much diff in non-linear elasticity exists between wood vs composite blades. Specifically, in wood blades the harder layer is on the outside, but with composite, there's an even harder layer just below. So does that change significantly change elastic response at lower speeds or what? |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 2:06pm Posted: 08/14/2013 at 2:06pm |

|

|

"Specifically, in wood blades the harder layer is on the outside, but with composite, there's an even harder layer just below"

Not always for wood blades (ex: a lot of blades have Limba in outer ply and an harder ply like Acajou, Koto under)... Not true at all for composite blades (ex: Koto/ALC/Ayous/Kiri or Hinoki/ALC/Limba/Kiri or Hinoki/ALC/Ayous/Kiri). Please refer to ttbdb database. It's just a complicated alchemy... |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 6:02pm Posted: 08/14/2013 at 6:02pm |

|

|

No, what I'm referring is that most composites have the significantly harder composite layer right under the softer wood top, except "soft carbon" design with either a thick top or carbon under two top wood layers.

Generally the overall rigidity should be similar regardless of stacking priority, but presumably putting the softer layer on top or other stacking strategy would change the low speed response more due to perhaps some surface behavior rather than elastic flex. Ie more energy loss by gently hitting wood rather than carbon. It's not obvious how much though, which is what I'm curious about. Edited by AgentHEX - 08/14/2013 at 6:04pm |

||

|

||

Baal

Forum Moderator

Joined: 01/21/2010 Location: unknown Status: Offline Points: 14336 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/14/2013 at 10:09pm Posted: 08/14/2013 at 10:09pm |

|

I think so too, but I also think the Maze is a bit of an outlier compared to Visc/TBS/TB-ALC, which are more similar to each other. Actually sometimes two Viscarias may be more different from each other than one of them is to a TBS. This has led to endless discussions about whether TBS or Viscaria is faster/softer/controllable and the correct answer is it depends on which one you get. TB-ALC is consistently a little crisper than the others, it seems like they have treated the outer layer of wood and it is almost shinier. Maybe JPG knows something about this? If so, I would like to know. The effect on how you play would be negligible once you got used to it. The Maze handle has a quite different shape, which to me makes more of a difference than the blade itself. It really doesn't fit my grip very well, the edges are really noticeable. All in all, I still prefer Viscaria to the others, but you can't make a bad choice to buy any of them -- but you should try one first. Edited by Baal - 08/14/2013 at 10:10pm |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/15/2013 at 3:49am Posted: 08/15/2013 at 3:49am |

|

|

"No, what I'm referring is that most composites have the significantly

harder composite layer right under the softer wood top, except "soft

carbon" design with either a thick top or carbon under two top wood

layers."

Not always (ex: Innerforce serie, Joola K serie or Rossi serie, Donic carbokev/Aratox/Carbotox, Nexy Spartacus, Adidas...) and soft carbon is refering to a type of carbon & not the position. I am not 100% sure that the way a blade will play is really predictable. Manufacturers do a lot of tests and propose a lot of solutions (ex: BTY has the same blades with composite in 2nd or 3rd position). Generally speaking: Carbone under the 1st ply of wood => less flex, more speed & gain in weight AL (Vectran)/ZL/Kevlar under the 1st ply of wood => more damping ALC/ZLC/Carbokev under the 1st ply => more power with reduction of vibration and flex added compared to carbon (+ weight gain) But regarding the composite in 3rd position, I really doubts that the results are really predictable under 2 plies of (different) woods. |

||

|

||

Dorje

Member

Joined: 04/21/2009 Location: Slovenia Status: Offline Points: 28 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 08/18/2013 at 12:35pm Posted: 08/18/2013 at 12:35pm |

|

|

Good points straits85.

If I can my add my view of difference between surface layers (M. Maze limba outer and Viscaria koto outer). I think that the surface layer (wood type and their characteristics) is the most important thing that determines what could be called, "blade feeling" for the touch, especially for close to the table play and soft touches. Different wood types have different characteristics, hence the feeling for each of them would be very different. So the same blade, even made by the same company, sometimes feel a little bit different (for expirienced player), so of course having different surface layer wood, would make the blade entirely different in feel. This outer layer of wood (surface layer) is 1st to come into contact with the ball through the wood that is directly attached to the rubber, which is directly in contact with your fingers on the handle. So of course, it will affect your feeling. At that point I am only thinking at the surface layer wood types (the biggest determinant for all aspects of hand-feeling), and not the 2nd layer, or the inner core layer of wood. Inner core layer and composition of the blade itself (also thickness of layers) would involve the blade's stability, crispness and stiffnes and the power feeling when a powerful shot is executed. Each of this layers have their own unique characteristics and combination with other wood layers are bringing the best out of the blade, hence players that have certain stile can choose what suits them accordingly. Back to the difference of the two mensioned blades. Surface layers of limba and koto is basically the only big difference as they are otherwise almost the same composition (second is ALC, third is limba and core is kiri). Here are some key characteristics of limba and koto, not to write long, detailed and elaborate description: Limba: Limba has quite long dwell time so it is great for players who prefers that spin is generated with the rubbers sponge not as much as with the topsheet. Limba by itself has low speed due to long dwell time, which is probably (correct me if I am wrong) due to the loosely connected wood fibres of the wood type (which is also the reason why it sometimes splinters off). Limba is suitable for players who prefers to hold the ball longer on the racket and those who prefer to generate the power shots by himself. Some players for example: Jun Mizutani, Vladimir Samsanov, Petr Korbel. My expirience with some limba outer layered rackets is that thay are a bit non linear when you give more power to the shots. Also I find the throw of the ball coming off much higher with more power, or maybe it's the combination of different wood that gave me this feeling. It is very hard for me to play with limba surfaced blades, for the life of me, I could not get in good terms with any of them, just to notice some of them (Joola Fever, M. Maze, Stiga Clipper, Joola Viva, Korbels...) Koto: Koto has short dwell time so it is great for players who prefers that spin is generated more with the rubbers topsheet than sponge. It has good speed for smashes due to short dwell time. Fibres are quite densely connected, hence it usually does not splinter off. It is suitable for players who likes to "rebound" the ball back for the soft touches, doesn't like the ball to stay on the blade too long. It is good for close to the table attackers. Under that quite hard koto surface layer we do not see second layer as carbon only (carbon is always mixed with some other type of fiber: Arylate, Aramid, Kevlar, Zylon...). If second layer is pure carbon, than the blade has ussually hinoki surface. For me blades with koto outer feel the best (I play with Timo Boll Spirit). I can block balls with koto outer much more consistently than with blades that has limba outer. All in all, when choosing the blade for yourself, looking at the surface layer wood would be one of the most important, if not the most important factor. This is to consider when you change your old blade for a new one. The best equipment choice for a player is a combination of how comfortable you are with this blade and if it is suitable for your kind of playstile. I have seen many, many players, who somehow chose a new blade just by popularity or looks and not knowing anything about it. So it's good to know something about wood types and fibers. Hopefully adding these information will give Janekb somekind of insight in the differences between this two Butterfly blades. |

||

|

Timo Boll Spirit An

Fh: Joola Rhyzm Max red Bh: Tibhar Aurus Max black |

||

|

||

Baal

Forum Moderator

Joined: 01/21/2010 Location: unknown Status: Offline Points: 14336 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/18/2013 at 1:17pm Posted: 08/18/2013 at 1:17pm |

|

|

I also think that the surface layer is very important, and I agree with Straits to that it is not easy to predict. I strongly suspect differences in the gluing and curing procedures used in some of these blades must be quite important. This is because some blades with ostensibly identical composition play a lot differently than you would expect. Example, ZJK vs. Viscaria, which really feel very different. This is not something you can learn about from the manufacturer, so in the end you just have to try the blades yourself to see if you like them. On the other hand, they are all good blades and if you use any one of them for awhile, you will get used to its features. After all, they are all designed for the same general style of play -- offensive topspin oriented table tennis.

Edited by Baal - 08/18/2013 at 1:22pm |

||

|

||

janekb

Silver Member

Joined: 03/01/2012 Location: Illinois Status: Offline Points: 646 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/18/2013 at 1:29pm Posted: 08/18/2013 at 1:29pm |

|

|

Thanks to all of you.I have chance to play Viscaria and MMaze ,Viscaria has better feel and is not as bouncy in the short game,I think I like Viscaria better.I got acudas1 turbo on fh with Viscaria and seems like sponge is to hard difficult dig to the sponge to create good spin but acuda s1 on bh works great,I guess I will keep playing with it maybe sponge will soften up after some time.

|

||

|

Janek B

|

||

|

||

Baal

Forum Moderator

Joined: 01/21/2010 Location: unknown Status: Offline Points: 14336 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/18/2013 at 7:58pm Posted: 08/18/2013 at 7:58pm |

|

|

It's good that you got to try them first! The one thing I have discovered is that about 80% of the time I buy some rubber or blade to try because I read about on the web, I generally end up regretting it.

|

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 4:23am Posted: 08/19/2013 at 4:23am |

|

Soft carbon terminology is used to market blades with layer deeper under wood, and thus how I refer to them. Ovtcharov Soft Carbon, Yasaka Soft carbon, Galaxy W5, etc. If you believe it to be a different material, please explain the difference.

What specific properties of ALC/ZLC/Kevlar achieve the above descriptions? Self-validation is not the same thing. |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 4:37am Posted: 08/19/2013 at 4:37am |

|

|

I made a topic on the french forum with these composite physical properties.

I will try to find it, translate & post. |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 4:47am Posted: 08/19/2013 at 4:47am |

|

|

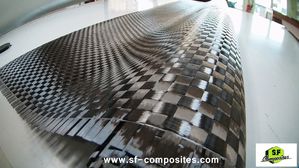

Soft carbon, uniaxial carbon, wawed carbon... is the way the carbon is woven or laminated (sorry, this technical words are a bit difficult to me).

Carbon can come in different ways (please refer to: http://materiaux-composites.over-blog.com/article-la-fibre-de-carbone-trame-couture-et-embuvage-48875798.html) It's in french but pictures are quite clear. |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:05am Posted: 08/19/2013 at 5:05am |

|

|

I finally found my sources:

http://csrbraids.com/index.php/kevlar-fiber.html http://fr.wikipedia.org/wiki/Mat%C3%A9riaux_%C3%A0_voile (for this one I am sure you can find it in english but charts are quite clear) To summarize: Regarding Arylate, this LCD polymer is in fact from Vectran which is a polyarylate fiber. This material is well known, for its elasticity, its wear resistance and high breaking limit. What is interesting in this fiber, widely used in the sailing and the aeronautics, are the following characteristics: - Exceptional damping characteristics - Excellent flex / folding characteristics It is a direct competitor of the Kevlar and Zylon in its applications (sails, cables, reinforcements of hulls, aeronautical parts). It is a little harder and heavy than Kevlar (and even more Aramid). Kevlar has with Vectran surprising capacities in traction & strain resistance. It has also high level of vibration absorption and shock resistance. Zylon is the newest composite, even more resistant but lighter. Compared to the others it resists better to high temperatures. On the other hand, its absorption capacities of the shocks are not very good. It gives less of flex that the others. Resistance (Take care, it is between 5 times & 10 times the one of the steel) Zylon > Vectran > Kevlar > Aramid Flexibility Zylon > Vectran > Kevlar Absorption of the shocks Vectran > Aramid > Kevlar > Zylon A fiber is even more interesting: Spectra. It is amazing that it still not appears in the ping! Better weight / resistance and huge damping capacities. |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:09am Posted: 08/19/2013 at 5:09am |

|

|

For information, Zylon recently lost the agreement of US National Institute of Justice ( NIJ)

which approves its use in bulletproof vests, because research demonstrated that it lost its antiballistic capacities much more quickly

than quite different material.

So take care to your ZL/ZLC blades ;=) |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:11am Posted: 08/19/2013 at 5:11am |

|

A lot of these use cases aren't in line w/ TT application. Sails, cables, etc, is the fiber itself whereas "carbon" in blades is set in resin, and the "hardness" comes from the bonding epoxy. If you've ever handled these materials, the sheets are basically thin fabric-like soft. |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:26am Posted: 08/19/2013 at 5:26am |

|

|

"whereas "carbon" in blades is set in resin" => not so sure. Inserts are carbon leaf assembled with glue (epoxy or not, depending of the manufacturer). You can use it when you try to build your own blade (some of these manufacturers are on the forum I think).

"the "hardness" comes from the bonding epoxy" => partially true only. |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:44am Posted: 08/19/2013 at 5:44am |

|

|

Again, if you've ever handled the fabric, it's pretty obvious the hardness is basically zero. Something like bulletproof vest also isn't exactly interested in the low-impact elasticity as we are.

When the fabric is hardened enough to be load supporting, I would think the resins which cure at ambient vs requiring a high-temp autoclave are quite different. Also, whereas performance per unit mass/thickness might be critical enough in some applications that 20% diff matters, hardness varies polynomially with thickness in what is already paper thin layer in TT so any such diff is likely irrelevant. Ie, twice as thick layer is maybe 8 times harder which would dwarf the fabric material. Edited by AgentHEX - 08/19/2013 at 5:55am |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 5:57am Posted: 08/19/2013 at 5:57am |

|

|

Too bad you can not read french and I am too lazy to translate:

http://materiaux-composites.over-blog.com/article-la-fibre-de-carbone-trame-couture-et-embuvage-48875798.html Please see Par. 3 "Embuvage" to explain the role of the stratification. In composite materials fibers bring the resistance while the matrix (resin) allows them to support the loads of compression. There are 3 types of fibers (fiber weaved or not) which will be soaked with resin: fiberglasses, carbon, aramide (Kevlar ®). |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 6:05am Posted: 08/19/2013 at 6:05am |

|

Here are the composite fibers (that's what you get after "embuvage"). Then you use epoxy resin or polyester resin. |

||

|

||

AgentHEX

Gold Member

Joined: 12/14/2004 Location: Yo Mama Status: Offline Points: 1641 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 6:07am Posted: 08/19/2013 at 6:07am |

|

|

I've glanced over similar reading material in english. However I/we don't know how exactly butterfly make their composites.

It seems to me quite likely that "ALC" vs "carbon" vs "kevlar" make for better marketing material compared to 0.11mm vs 0.12mm vs resin X @ 20deg vs resin Y @ 50deg, even though construction details can easily vary FAR more than fabric itself. It's possible they purposely constructed each to approximate their "general description", ie make the arylate blades' layer slightly thinner and therefore "softer". In case of such coincidental marketing correlation, attributing property lists to results (ie causal) is at best accidentally correct. Edited by AgentHEX - 08/19/2013 at 6:09am |

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 6:21am Posted: 08/19/2013 at 6:21am |

|

|

I think their ALC/ZLC composite is that one:

but with one carbon fiber and one vectran/zylon fiber in each direction (I think it's explained on BTY or Xiom website). I also guess they use either 12k/400tex fiber or 24k/800tex fiber to minimize the price. I do not know about the Epoxy they use (EPOXY 1040, 1045N, 1048N...) ? |

||

|

||

Baal

Forum Moderator

Joined: 01/21/2010 Location: unknown Status: Offline Points: 14336 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 9:09am Posted: 08/19/2013 at 9:09am |

|

|

Do you have any idea why zylon is so expensive? Is it also more expensive in other applications?

|

||

|

||

straits85

Super Member

Joined: 05/09/2013 Location: France Status: Offline Points: 154 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 08/19/2013 at 9:48am Posted: 08/19/2013 at 9:48am |

|

|

Price should not be so expensive !

There is a very small quantity of Zylon fiber in the blades and Zylon is widely used for ropes and a lot of other applications. I think it is just a question of marketing. Hey, look: there is a new composite fiber and we use it in our blades... Come on: it has been developped for more than 30 years !! |

||

|

||

Post Reply

|

Page <1 2345> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |

|

Forum Home | Go to the Forums | Forum Help | Disclaimer

MyTableTennis.NET is the trading name of Alex Table Tennis Ltd. |